Asphalt mixing plant models are typically classified based on their production capacity (tons/hour), structural form, and process flow.

1. Classification by Operation Method

Stationary Asphalt Mixing Plant

Features: Installed on a fixed site, they are large-scale, feature high production capacity, and are highly automated. \”Batch metering and batch mixing\” means that the heating, drying, screening, and metering of aggregate (sand and gravel) are performed separately from the metering of asphalt and mineral powder, with forced mixing finally taking place in the mixing tank.

Applicable Applications: Large-scale projects, urban commercial asphalt concrete supply, and long-term projects.

Mobile Asphalt Mixing Plant

Features: Major components are modularized and mounted on trailers, allowing for rapid transport and installation. From aggregate drying and heating to mixing with asphalt and mineral powder, the entire process is continuous. While production efficiency is high, metering accuracy and mix quality stability are slightly lower than those of intermittent plants.

Applicable Applications: Highway maintenance, small and medium-sized projects, and projects with dispersed construction sites.

2. Classification by Production Capacity

This is the most intuitive classification and directly reflects the scale of the equipment.

- Small: Under 40 t/h

- Medium: 60-160 t/h

- Large: 180-320 t/h

- Extra-large: Over 400 t/h

In summary: In the market, when people refer to \”asphalt mixer,\” they typically refer to fixed, forced-intermittent asphalt concrete mixing equipment.

II. Working Principle (Taking Forced-Intermittent Type as an Example)

The operating process of a forced-intermittent asphalt mixing plant is a sophisticated, interconnected system.

The entire process can be divided into the following key stages:

- Cold Material Supply and Initial Mixing

Sand and gravel aggregates (such as crushed stone, sand, and stone chips) of varying specifications (particle sizes) are stored in cold material silos and conveyed by a belt feeder to the aggregate conveyor according to a preliminary proportion for delivery to the next stage. - Aggregate Drying and Heating

The aggregate conveyor feeds the cold, wet aggregate into the drying drum. Inside the drying drum, the aggregate is directly heated by a countercurrent of high-temperature flames (generated by a burner). As the drum rotates, it is continuously lifted and dispersed, fully removing moisture and reaching an operating temperature of approximately 160-180°C. - Hot Aggregate Screening and Storage

The heated aggregate is conveyed by an elevator to a vibrating screen. The vibrating screen accurately sorts the aggregate by particle size into different hot aggregate silos. This step is critical to ensuring the precise gradation of the final mixture. - Precision Metering and Mixing

This is the \”brain\” and core of the entire equipment:- Aggregate Metering: The control system accurately weighs the required weight of aggregate of varying particle sizes from each hot aggregate silo according to the recipe and places it into the mixer.

- Asphalt Metering: Asphalt is heated to a liquid state in an insulated tank, accurately metered using an asphalt scale, and then sprayed into the mixer.

- Mineral Powder Metering: The mineral powder in the mineral powder silo is conveyed by a screw conveyor to a mineral powder scale, where it is accurately metered and added to the mixer. All materials are forcefully mixed within the mixer, uniformly blending into high-quality asphalt concrete in a short time (approximately 30-45 seconds).

- Finished Material Storage and Loading

The finished asphalt mixture is unloaded into a finished material silo for temporary storage or directly loaded onto a truck, covered with an insulating tarp, and transported to the construction site for paving.

Advantages of Forced Batch Asphalt Mixing Plants:

High Mix Quality and Precise Grading

Because the aggregates are precisely screened and stored in separate silos, metering can be performed strictly according to the designed formula, ensuring a highly accurate and stable mineral gradation (i.e., the proportion of various aggregate sizes) in the asphalt mixture. This is crucial for ensuring pavement quality (such as smoothness and durability).

Flexible Recipe Adjustment

Changing recipes is easy. Simply modifying parameters in the control computer allows you to produce asphalt mixtures of different specifications and types (such as AC, SMA, OGFC, etc.) to meet various project requirements. Good Environmental Performance

Modern batch equipment is equipped with efficient bag filters, which capture most of the dust generated during the drying drum and mixing process. The recovered dust can be used as mineral fines, reducing pollution and waste.

Mature Technology and High Reliability

As a classic model developed over decades, its technology is very mature, operation is stable, failure rates are relatively low, and maintenance is easy.

Advantages of Continuous Asphalt Mixing Plants:

High Production Efficiency

Because it operates continuously, there is no waiting time associated with the intermittent “loading-mixing-discharging” cycle, resulting in higher theoretical output at the same power output.

Low Energy Consumption

The relatively simple structure, lacking a bulky vibrating screen or hot silo system, results in lower overall energy consumption.

Small Footprint and Low Investment Cost

With its compact design, initial investment and installation costs are generally lower than those of batch equipment of the same output.

When choosing an asphalt mixer, forced batch asphalt mixers are the preferred choice for most high-standard projects due to their superior mix quality, flexible formulation adaptability, and excellent environmental performance. Continuous asphalt mixers, on the other hand, are valuable in cost-sensitive applications with extremely high production requirements and less demanding mix gradation accuracy.

CO-NELE’s full-scenario solution covers everything from road construction to road maintenance.

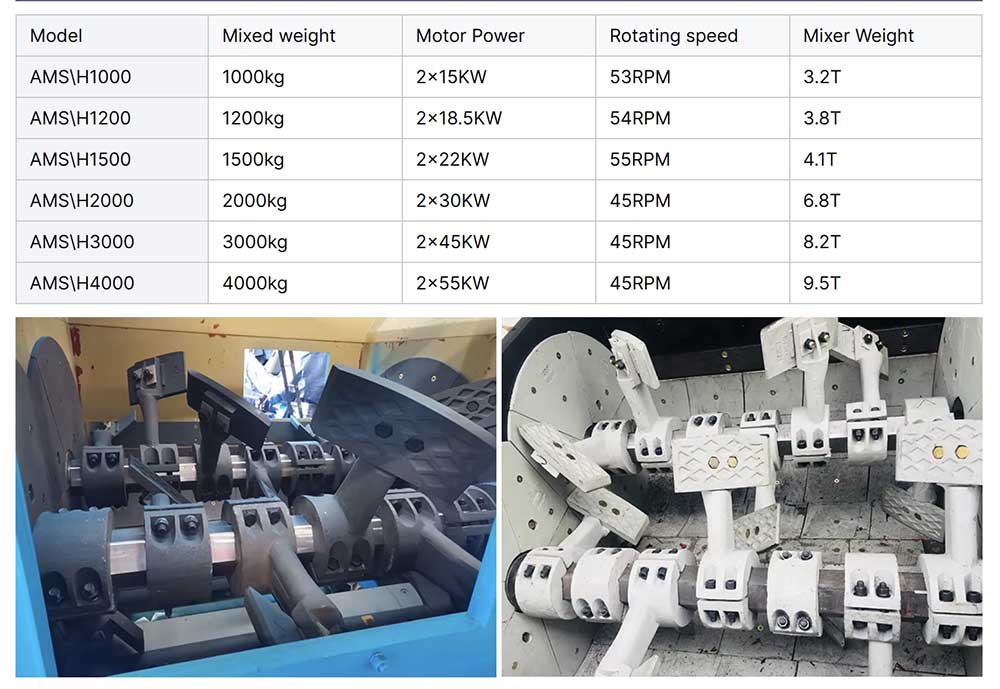

Large-scale infrastructure projects: For highways and airport runways, high-capacity models like the CO-NELE AMS\H4000 deliver mix strength exceeding 12 MPa and 25% improved rutting resistance, meeting the demands of heavy traffic loads.

Municipal road construction: The CO-NELE AMS\H2000 series supports dual-mode production, combining virgin and recycled materials, balancing construction efficiency and environmental protection. It is the optimal choice for surface construction on urban expressways and main roads.

Road maintenance and repair: CO-NELE’s small, mobile models (60-120 t/h) flexibly navigate urban streets, producing on-site, reducing transportation losses and shortening maintenance work by 50%.

Special Project Needs: CO-NELE offers customized warm-mix asphalt and foamed asphalt production modules, enabling low-temperature mixing at 120°C and reducing noise by 15dB, making them suitable for special scenarios such as sponge cities and scenic road conditions.

CO-NELE Asphalt Mixer Full Lifecycle Service

24-hour Rapid Response: Remote diagnosis resolves 80% of faults, with engineers arriving on-site within 48 hours.

Customized Upgrade Service: We offer an “Intelligent Asphalt Mixer Retrofit Solution” for older equipment, including the installation of CO-NELE IoT modules and upgraded dust removal systems, bringing new production capacity to older equipment.

CO-NELE Certifications Back Your Quality

CO-NELE products are certified by international authorities such as ISO 9001, ISO 14001, and CE, and are exported to over 80 countries worldwide.

Post time: Oct-15-2025