Matakin haɗa gilashi na farko yana da matuƙar muhimmanci ga ƙera gilashi. Ba tare da daidaito ba, ba tare da daidaito ba yana haifar da lahani, rage yadda ake narkewa, da kuma ƙaruwar amfani da makamashi. An ƙera mahaɗan mu daidai gwargwado don kawar da waɗannan matsalolin, don tabbatar da cewa shirya gilashin ku ya kasance daidai, inganci, kuma mafi girman matsayi.

Muna bayar da nau'ikan mahaɗa guda biyu daban-daban don biyan buƙatun daban-daban na samar da gilashi na zamani: mai laushi amma mai zurfiInjin Haɗawa na Duniya don Gilashida kumaMai haɗa gilashi mai ƙarfi sosai.

NamuInjin Haɗa Gilashin Duniyaan tsara shi ne don aikace-aikacen da ke buƙatar aikin haɗa abubuwa masu kyau da kuma sarrafawa. Ya dace da haɗa abubuwa masu laushi ko kuma inda aka fi son tsari mai laushi don hana lalacewar ƙwayoyin cuta.

Muhimman Abubuwa & Fa'idodi:

Aikin Taurari Mai Kyau: Ruwan da ke juyawa yana kewaya jirgin ruwan cakuda a lokaci guda kuma yana juyawa a kan hanyarsa, yana tabbatar da cewa an motsa kowace ƙwayar cuta ta yankin haɗawa ba tare da tabo marasa kyau ba.

Rufin da Aka Yi Daidai: Yana shafa kayan da suka lalace kamar yashi silica da danshi mai daidaito (ruwa ko soda mai kauri) da sauran abubuwan ƙari, yana hana rabuwa.

Saurin Saurin Canji: Masu aiki za su iya daidaita saurin haɗuwa da lokaci daidai don cimma cikakkiyar haɗuwa don takamaiman girke-girke, daga foda mai kyau zuwa gaurayawan granular.

Sauƙin Tsaftacewa da Kulawa: An tsara su ne da la'akari da sauƙin shiga, na'urorin haɗa mu na duniya suna ba da damar sauyawa cikin sauri tsakanin rukuni da tsaftacewa mai sauƙi don hana gurɓatawa.

Gine-gine Mai Tsauri: An gina shi da kayan aiki masu ɗorewa waɗanda ke jure wa yanayin lalata kayan gilashin, wanda ke tabbatar da tsawon rai da aminci.

Ya dace da: Gilashin Soda-lime, gilashin musamman, zare na gilashi, da kuma rukunoni masu ɗauke da cullet da aka sake yin amfani da shi.

Injin Haɗa Gilashi na Duniya: Daidaito da Haɗawa Mai Sauƙi

| Masu Haɗa Gilashi | CMP250 | CMP330 | CMP500 | CMP750 | CMP1000 | CEMP1500 | CMP2000 | CMP3000 | CMP4000 | CMP5000 |

| Ƙarfin haɗa kayan da aka yi da gilashi/Lita | 250 | 330 | 500 | 750 | 1000 | 1500 | 2000 | 3000 | 4000 | 5000 |

Ga ayyukan da ke buƙatar haɗuwa cikin sauri da ƙarfi, Injinan Haɗa Gilashi masu ƙarfi suna ba da aiki mara misaltuwa. Waɗannan mahaɗan suna amfani da na'urar juyawa mai sauri don ƙirƙirar aiki mai ƙarfi na ruwa, suna cimma cakuda iri ɗaya a cikin ɗan gajeren lokacin zagayowar.

Muhimman Abubuwa & Fa'idodi:

Aikin Haɗawa Mai Sauri: Yana rage lokacin haɗawa sosai idan aka kwatanta da hanyoyin gargajiya, yana ƙara yawan aikin samarwa da inganci.

Watsawar Ruwa Mai Kyau: Yana da tasiri sosai wajen rarraba ƙananan ruwaye masu ɗaurewa (misali, ruwa) a cikin dukkan tsari, yana ƙirƙirar cakuda mai kama da juna wanda ke rage ƙura da inganta narkewa.

Ingantaccen Makamashi: Yana cimma cikakkiyar haɗuwa cikin sauri, yana rage yawan amfani da makamashi a kowane rukuni.

Tsarin da ke hana ƙura shiga: Ginin da aka rufe yana ɗauke da ƙura, yana inganta muhallin aiki mai tsafta da aminci da kuma rage asarar kayan aiki.

Gine-gine Masu Nauyi: An ƙera su don jure wa ayyukan haɗa abubuwa masu wahala da wahala kowace rana.

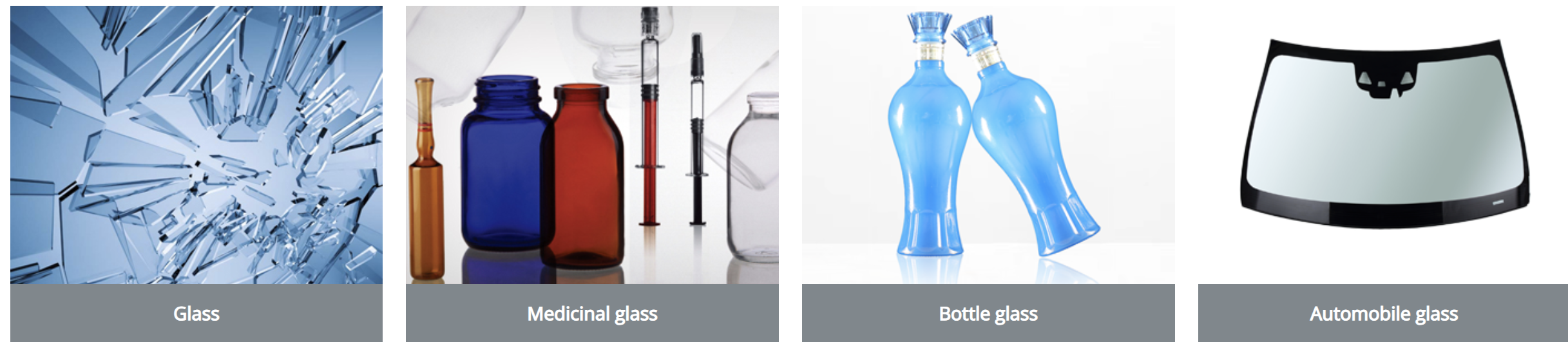

Ya dace da: Gilashin kwantena, gilashin lebur, layukan samarwa masu yawa, da kuma rukuni inda watsa danshi mai inganci yake da mahimmanci.

Injin Haɗawa Mai Ƙarfi don Gilashisigogi

| Injin Haɗawa Mai Ƙarfi | Ƙarfin Samarwa na Awa-Awa: T/H | Yawan Haɗawa: Kg/baki | Ƙarfin Samarwa:m³/h | Rukunin/Lita | Fitar da caji |

| CR05 | 0.6 | 30-40 | 0.5 | 25 | Fitar da ruwa ta tsakiya |

| CR08 | 1.2 | 60-80 | 1 | 50 | Fitar da ruwa ta tsakiya |

| CR09 | 2.4 | 120-140 | 2 | 100 | Fitar da ruwa ta tsakiya |

| CRV09 | 3.6 | 180-200 | 3 | 150 | Fitar da ruwa ta tsakiya |

| CR11 | 6 | 300-350 | 5 | 250 | Fitar da ruwa ta tsakiya |

| CR15M | 8.4 | 420-450 | 7 | 350 | Fitar da ruwa ta tsakiya |

| CR15 | 12 | 600-650 | 10 | 500 | Fitar da ruwa ta tsakiya |

| CRV15 | 14.4 | 720-750 | 12 | 600 | Fitar da ruwa ta tsakiya |

| CRV19 | 24 | 330-1000 | 20 | 1000 | Fitar da ruwa ta tsakiya |

Kwarewa Mai Inganci: Co-nele tana da shekaru 20 na gwaninta a masana'antar gilashi, tana samar da ingantacciyar fasaha don haɗawa da shirya kayan gilashi.

Mafita Masu Daidaita: Mu a Co-nele muna ba da nau'ikan mahaɗan gilashi iri-iri (gami da mahaɗan CMP Series na duniya da mahaɗan CR Series masu ƙarfi) don biyan buƙatunku na musamman na iya aiki da tsari.

Mayar da hankali kan inganci: Kowace na'urar hadawa ta cika ƙa'idodin masana'antu na Turai don tabbatar da dorewa, aiki, da kuma samun riba mai sauri akan jari.

Abokan ciniki 10,000 a duk duniya suna goyon bayansu: Tallafin fasaha da hanyar sadarwar kayayyakin gyara suna tabbatar da aiki cikin sauƙi a duk duniya.

Tushen Gilashin Inganci Ya Fara Da Haɗawa Mai Kyau

Zuba jari a hannun damaInjin Haɗa Gilashi Batchsaka hannun jari ne a cikin inganci, inganci, da kuma ribar dukkan tsarin ƙera gilashin ku.

Shin kuna shirye don inganta haɗa gilashin ku? Tuntuɓi mu a yau don tattauna aikace-aikacen ku da kuma nemo madaidaicin mahaɗin da ya dace da buƙatunku.

Babban Kayan Gilashin Gilashi

Silicon dioxide (SiO₂): Wannan shine mafi mahimmancin gilashin da aka yi amfani da shi, wanda ya ƙunshi mafi yawan gilashin (kamar gilashin lebur da gilashin akwati). An samo shi daga yashi mai siffar quartz (yashi mai siffar silica), yana ba da tsarin kwarangwal na gilashin, ƙarfin tauri, kwanciyar hankali na sinadarai, da juriyar zafi. Duk da haka, yana da ma'aunin narkewa mai yawa (kimanin 1700°C).

Tokar Soda (sodium carbonate, Na₂CO₃): Babban aikinsa shine rage yawan narkewar silica (zuwa kimanin 800-900°C), ta haka yana adana kuzari mai yawa. Duk da haka, yana kuma sa gilashi ya narke a cikin ruwa, yana samar da abin da aka fi sani da "gilashin ruwa."

Potassium carbonate (K₂CO₃): Kamar yadda yake da ash na soda, ana amfani da shi wajen kera wasu tabarau na musamman, kamar gilashin gani da gilashin fasaha, yana ba da haske da halaye daban-daban.

Dutse mai laushi (calcium carbonate, CaCO₃): Ƙara tokar soda yana sa gilashi ya narke a cikin ruwa, wanda ba a so. Ƙara tokar dutse yana rage wannan narkewar, yana sa gilashin ya zama mai dorewa kuma mai ɗorewa. Hakanan yana ƙara tauri, ƙarfi, da juriyar yanayi na gilashi.

Magnesium oxide (MgO) da aluminum oxide (Al₂O₃): Ana kuma amfani da waɗannan a matsayin masu daidaita abubuwa, suna inganta juriyar sinadarai, ƙarfin injina, da juriyar girgizar zafi na gilashi. Yawanci aluminum oxide ana samunsa ne daga feldspar ko alumina.

A taƙaice dai, gilashin soda-lime-silica da aka fi amfani da su (tagogi, kwalabe, da sauransu) ana yin su ne ta hanyar haɗa yashi mai siffar quartz, ash na soda, da kuma farar ƙasa.

Na baya: Masu haɗa yashi mai ƙarfi Na gaba: 25m³/h Masana'antar Batching na Siminti