Stupalith, a specialized ceramic material known for its exceptional durability and thermal stability, is widely used in high-temperature industrial applications. The production process requires precise mixing and granulation to achieve the desired material properties. A leading manufacturer faced challenges with traditional equipment, including uneven mixing, poor granule density, and low production efficiency.

Solution

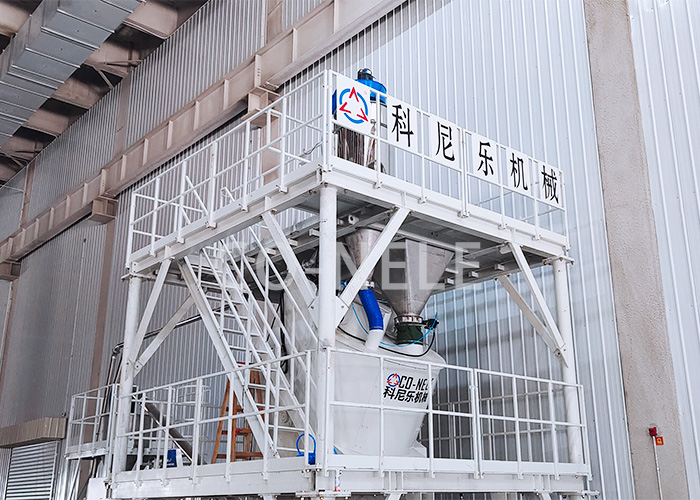

CONELE’s Intensive Mixing Granulator for Stupalith production line.

- Tilted Barrel Design + High-Speed Rotor System: Creates a counter-rotating shear force, generating a three-dimensional turbulent mixing field that eliminates dead zones and ensures 100% uniformity, even with trace additives as low as 0.1% .

- Intelligent Control System: Utilizes PLC and temperature/humidity sensors to precisely control rotational speed, temperature, and other parameters. This allows for preset process recipes and real-time adjustments, crucial for maintaining consistent pellet quality and avoiding issues like mold sticking .

- Multi-Function Capability: Integrates mixing, granulation, and fiberization processes into a single machine, significantly shortening the production chain .

- High Wear Resistance: Equipped with special wear-resistant liners and blades,prolonging service life and reducing maintenance costs .

- Quick and Clean Discharge: Features a patented discharge system that ensures thorough and rapid material discharge without leakage .

Results Achieved

- Enhanced Product Quality: The uniform dispersion of binders and additives achieved by the CONELE granulator significantly improved the particle density and spherical of the Stupalith granules. This leads to higher green body density and improved sintering performance in subsequent processes .

- Increased Production Efficiency: The integrated mixing and granulation process within a single unit reduced the overall production cycle time by an estimated 30-50% compared to traditional methods .

- Improved Operational Stability: The robust design and precise control system minimized downtime and ensured consistent, repeatable batch-to-batch quality .

- Reduced Energy Consumption: The efficient mixing action and shorter processing times contributed to lower energy consumption per unit of product .

The application of the CONELE Intensive Mixing Granulator in Stupalith production demonstrates its capability to address critical challenges in advanced ceramic manufacturing. By delivering superior mixing uniformity, enhancing granule quality, boosting efficiency, and ensuring process reliability, CONELE’s equipment has proven to be a valuable asset for manufacturers aiming for high-performance materials and optimized production workflows.

Post time: Sep-15-2025