Stupalith, thepa e khethehileng ea letsopa e tsejoang ka ho tšoarella ha eona ho ikhethang le botsitso ba mocheso, e sebelisoa haholo lits'ebetsong tsa indasteri tse nang le mocheso o phahameng. Ts'ebetso ea tlhahiso e hloka ho kopanngoa le ho kopanngoa ka nepo ho fihlela thepa e lakatsehang ea thepa. Moetsi ea ka sehloohong o ile a tobana le liphephetso ka lisebelisoa tsa setso, ho kenyeletsoa ho kopanya ho sa lekanang, bongata bo fokolang ba li-granule, le katleho e tlase ea tlhahiso.

Tharollo

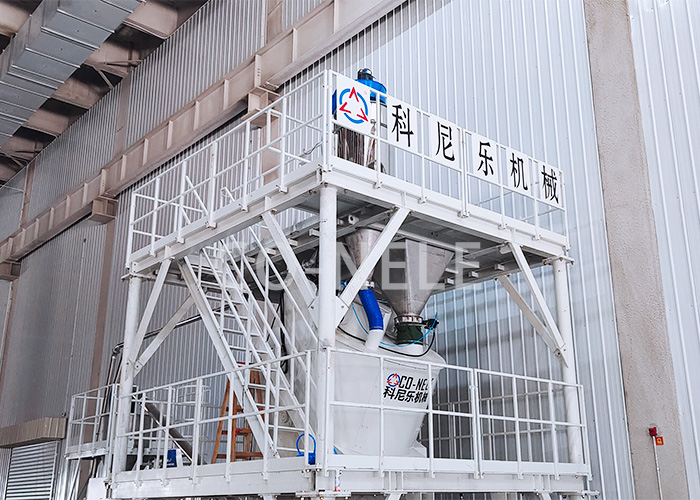

Granulator e Matla ea ho Kopanya ea CONELE bakeng sa mohala oa tlhahiso oa Stupalith.

- Moralo oa Moqomo o Tilted Barrel + Sistimi ea Rotor e Potlakileng: E theha matla a ho kuta a potolohang, e hlahisa tšimo ea ho kopanya e nang le maqhubu a mararo e felisang libaka tse shoeleng le ho netefatsa ho tšoana ka 100%, esita le ka litlatsetso tse ka tlase ho 0.1%.

- Sistimi ea Taolo e Bohlale: E sebelisa PLC le li-sensor tsa mocheso/mongobo ho laola lebelo la ho potoloha, mocheso le liparamente tse ling ka nepo. Sena se lumella diresepe tsa ts'ebetso tse seng li ntse li le teng le liphetoho tsa nako ea sebele, tsa bohlokoa bakeng sa ho boloka boleng bo tsitsitseng ba pellet le ho qoba mathata a kang ho khomarela hlobo.

- Bokgoni ba Mesebetsi e Mengata: E kopanya ditsamaiso tsa ho kopanya, ho kopanya le ho kopanya dikhoele le ho kopanya dikhoele mochining o le mong, e leng se kgutsufatsang ketane ya tlhahiso haholo.

- Ho Hanela ho Tloha ho Hoholo: E na le li-liner le mahare a khethehileng a sa tsofaleng, a lelefatsang bophelo ba ts'ebeletso le ho fokotsa litšenyehelo tsa tlhokomelo.

- Ho Ntša ka Potlako le ka Bohloeki: E na le sistimi ea ho ntša lintho e nang le patente e netefatsang ho ntšoa ha lintho ka botlalo le ka potlako ntle le ho lutla.

Liphetho tse fihletsoeng

- Boleng bo Ntlafalitsoeng ba Sehlahisoa: Ho hasana ho tšoanang ha li-binder le li-additi tse fihletsoeng ke granulator ea CONELE ho ntlafalitse haholo bongata ba likaroloana le chitja tsa li-granule tsa Stupalith. Sena se lebisa ho bongata bo phahameng ba 'mele bo botala le ts'ebetso e ntlafetseng ea ho sintering lits'ebetsong tse latelang.

- Keketseho ea Bokgoni ba Tlhahiso: Ts'ebetso e kopaneng ea ho kopanya le ho kopanya ka har'a yuniti e le 'ngoe e fokolitse nako ea potoloho ea tlhahiso ka kakaretso ka 30-50% ha e bapisoa le mekhoa ea setso.

- Botsitso bo Ntlafetseng ba Ts'ebetso: Moralo o tiileng le sistimi e nepahetseng ea taolo li fokolitse nako ea ho se sebetse 'me li netefalitse boleng bo tsitsitseng, bo ka phetoang batch-to-batch.

- Tšebeliso e Fokotseng ea Matla: Ketso e sebetsang hantle ea ho kopanya le linako tse khutšoane tsa ts'ebetso li kentse letsoho ho fokotseng tšebeliso ea matla ka yuniti ea sehlahisoa.

Tšebeliso eaCONELE Intensive Mixing Granulatortlhahiso ea Stupalith e bonts'a bokhoni ba eona ba ho sebetsana le liphephetso tse kholo tlhahisong e tsoetseng pele ea letsopa. Ka ho fana ka ho tšoana ho hoholo ha ho kopanya, ho ntlafatsa boleng ba granule, ho eketsa bokhoni, le ho netefatsa ts'epo ea ts'ebetso, lisebelisoa tsa CONELE li ipakile e le letlotlo la bohlokoa bakeng sa bahlahisi ba ikemiselitseng ho fumana thepa e sebetsang hantle le mesebetsi e ntlafalitsoeng ea tlhahiso.

Nako ea poso: Loetse-15-2025