The ramming material in the unshaped refractory material adopts a side smashing and side squeezing construction method, and the amorphous mixture is flowed and deformed to become a molded body, and a representative one is a beating molding. In the beating molding, the wet sand-like amorphous refractory material is called ramming material, which is different from the plastic-like and repairing material which is plastically deformed like an organic plastic. The ramming material does not need to be added with a low melting point binder, has high corrosion resistance and good thermal shock resistance, so it is mainly used as a high-grade amorphous refractory.

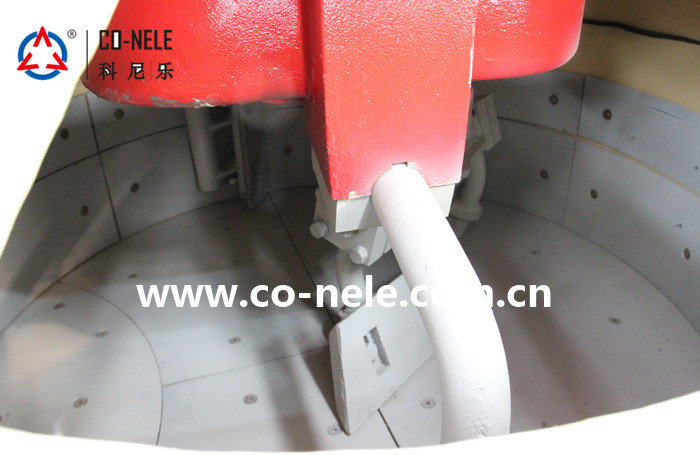

To mix and produce this ideal ramming material, the torque of the ramming mixer is larger than that of the powder mixing and the mud dispersion. It is recommended to use a vertical shaft planetary mixer – a professional ramming mixer. The crucible mixer is forced to shear, disperse and scrape.

Vertical shaft planetary ramming mixer features:

The refractory ramming material flows according to the set planetary agitation trajectory, and the operation is smooth. The material flow formed by the combination of the revolution and the self-rotation of the stirring device itself generates an interaction force, and a plurality of forces are combined. Forced mixing and mixing. Due to the specially designed mixing trajectory and the vertical shaft design of the mixer, the ramming mixer is added with side squeegee for auxiliary operation, and the entire mixer does not have a working inefficient area. The ramming mixer is cut and twisted by a high-speed flying knife to achieve uniform mixing of materials in a short time. Therefore, the ramming mixer can completely solve the problem of poor mixing quality of various materials.

The mixing trajectory of the ramming mixer is a non-dead angle trajectory curve with high mixing efficiency and high mixing efficiency after years of painstaking research and field test. The rotation of the ramming mixer’s trajectory is revolution. It is obtained by superimposing the rotation of the output agitation. This process belongs to the speed increasing mode. The mixing is fast and labor-saving. The trajectory curve belongs to the layer progressive and increasingly dense structure, so the ramming mixer has high homogeneity (high mixing uniformity). ), high mixing efficiency.

Post time: Jul-31-2018