CMP1000 planetary concrete mixer features a hard gear transmission system, designed to be noise-low, torque-large, and highly durable4. It can be equipped with an elastic coupling or hydraulic coupler (optional) for smooth start-ups even under full load conditions

1.mixing device

Mixing blades are designed in parallelogram structure(patented), which can be turned 180°for reuse to increase service life. Specialized discharge scraper has been designed according to discharge speed in order to increase productivity.

2. Gearing system

Driving system consists of motor and hardened surface gear which is specialized designed by CO-NELE (patented)

The improved model has lower noise, longer torque and more durable.

Even in strict production conditions, the gearbox can distribute power effectively and evenly to each mix end device

ensuring normal operation, high stability and low maintenance.

3. Discharging device

the discharging door can be opened by hydraulic,pneumatic or by hands.The number of the discharging door is three at most.

4.The hydraulic power unit

A special designed hydraulic power unit is used to provide power for more than one discharging gates.

5.Water spray pipe

The spraying water cloud can cover more area and also make the mixing more homogeneous.

Technical Specifications

The CMP1000 Planetary Concrete Mixer is designed with precision engineering to meet rigorous industrial standards. Here are the detailed technical specifications:

|

Model

|

Output

(L)

|

Input

(L)

|

Output

(kg)

|

Mixing power

( kW)

|

Planet/paddle

|

Side paddle

|

Bottom paddle

|

|

CMP1500/1000

|

1000

|

1500

|

2400

|

37

|

2/4

|

1

|

1

|

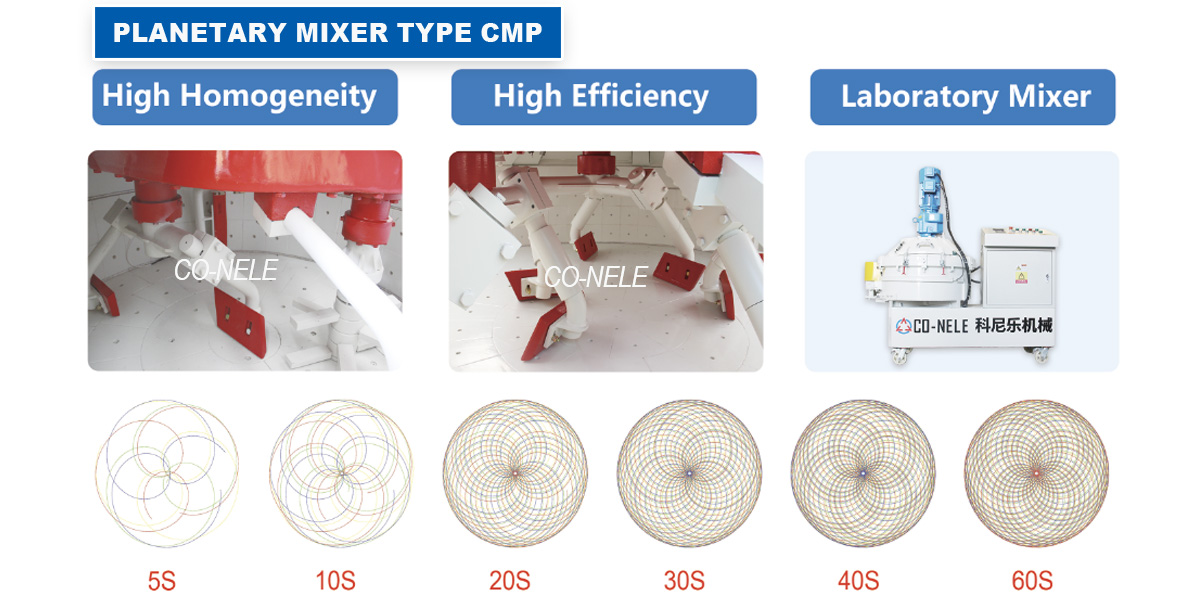

Product Advantages

Choosing the CMP1000 Planetary Concrete Mixer provides numerous tangible benefits:

Superior Mixing Quality: The planetary mixing mechanism ensures material is mixed violently and uniformly, achieving high homogeneity (mixing uniformity) and eliminating dead angles. This is crucial for high-end applications like UHPC.

High Efficiency and Productivity: The reasonable speed matching and complex motion (trajectory design) lead to faster mixing and shorter production cycles.

Robust and Durable Design: The hard gear reducer and patented parallelogram blades are built for longevity and withstand harsh production conditions.

Excellent Sealing Performance: Unlike some mixer types, the CMP1000′s design ensures no leakage problems, keeping the work area clean and reducing material waste.

Flexible Discharge Options: The capability for multiple discharge gates (up to three) provides flexibility for different production line layouts and requirements.

Ease of Maintenance: Features like the large maintenance door and reversible blades significantly reduce maintenance costs and downtime.

Environmentally Friendly: The sealed design prevents leakage, and the misting water system reduces water consumption and improves mixing efficiency

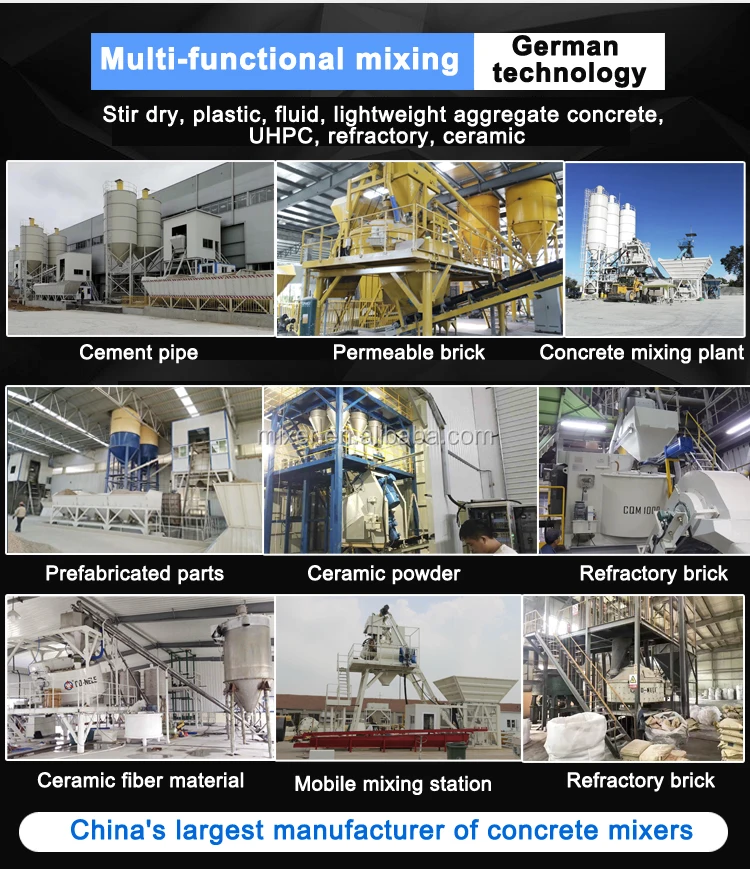

Product Structure & Design

The CMP1000 boasts a thoughtfully designed structure that enhances its performance and longevity:

Transmission System: Utilizes a motor-driven, company-specially-designed hard gear reducer (a patented product) for efficient power transfer and reliability.

Mixing Mechanism: Employs a planetary gear principle where the stirring blades perform both revolution and rotation. This creates complex, overlapping motion trajectories that cover the entire mixing drum, ensuring thorough, dead-angle-free mixing. The stirring blades are designed in a parallelogram structure (patented), which allows them to be rotated 180° for repeated use after wear, doubling their service life.

Discharge System: Offers flexible pneumatic or hydraulic discharge gate operation with up to three gates possible. The gates feature special sealing devices to prevent leaks and ensure reliable control.

Water Route System: Incorporates an upper-mounted water supply design (patented) to eliminate residual admixtures and water in the pipeline, preventing cross-contamination between formulas. It uses spiral solid cone nozzles for fine, even misting and wide coverage.

Maintenance Features: Includes a large-size maintenance door with a safety switch for easy access, inspection, and cleaning

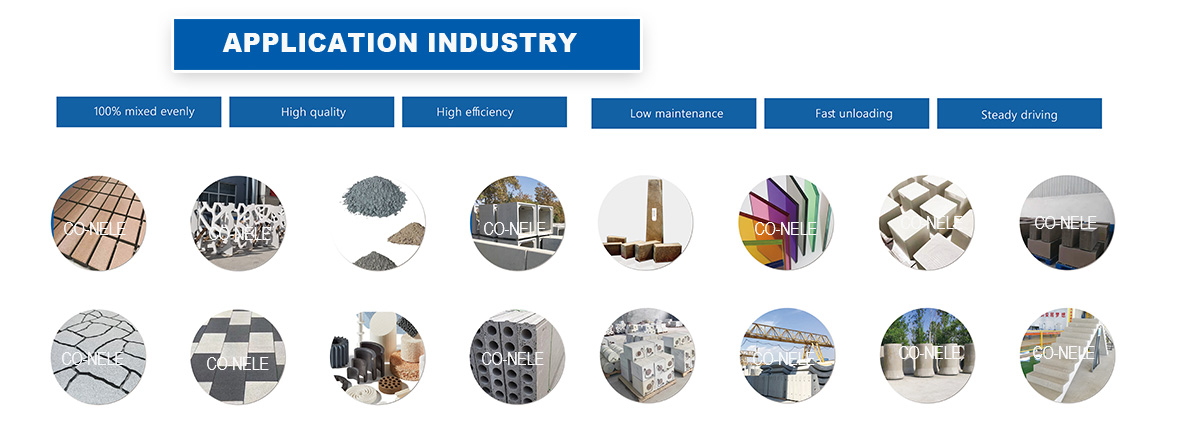

Application Industries

The CMP1000 Planetary Mixer is engineered for versatility across multiple sectors. Its robust design and efficient mixing action make it suitable for a wide range of materials:

Precast Concrete Components: Ideal for producing PC components, piles, sleepers, subway segments, ground tiles, and stair protections1. It excels in mixing dry-hard, semi-dry-hard, plastic concrete, UHPC (Ultra-High Performance Concrete), and fiber-reinforced concrete.

Construction Industry: Essential for large-scale engineering and construction projects requiring high-quality, consistent concrete.

Heavy Chemical Industry: Effectively mixes materials for glass, ceramics, refractory materials, casting, metallurgy, and environmental protection applications.

Specialized Material Processing: Capable of handling mineral slag, coal ash, and other raw materials requiring high homogeneity and strict particle distribution

About Co-Nele Machinery

Co-Nele Machinery Co., Ltd. is a high-tech enterprise with over two decades of experience in designing and manufacturing industrial mixing equipment. The company boasts major production bases and holds over 100 national patents. It has been recognized as a “Shandong Province Manufacturing Single Champion Enterprise” and a “Shandong Province ‘Specialized, Refined, Unique, and New’ SME”.

With a commitment to innovation and quality, Co-Nele has served more than 10,000 enterprises worldwide and has collaborated with prestigious institutions and companies like Tsinghua University, China State Construction (CSCEC), and China Railway (CREC). Their products are exported to over 80 countries and regions, solidifying their international reputation.

Customer Reviews

Co-Nele’s mixers have received positive feedback from a global clientele:

“The CMP1000 mixer has significantly improved our precast component quality and shortened mixing time. Its reliability has reduced our maintenance costs.” – A project manager from a leading construction firm.

“We use it for mixing refractory materials. Its high uniformity is impressive. The service from Co-Nele is also professional and responsive.” – A production supervisor in the heavy industry sector.

“After switching to Co-Nele’s planetary mixer, our production efficiency saw a noticeable increase. The equipment is strong and stable even under continuous operation.” – An equipment manager in the building materials industry.

The CMP1000 Planetary Concrete Mixer from Co-Nele Machinery is a testament to advanced engineering and practical design. It combines power, precision, and durability to meet the challenges of modern industrial mixing across diverse sectors. Whether you are producing high-performance precast concrete, processing refractory materials, or working on a specialized application, the CMP1000 offers a reliable and efficient solution designed to enhance your productivity and product quality.

Previous: MP750 Planetary concrete mixer

Next: CMP1500 Planetary concrete mixer