Superior Quality, High Efficiency: Complete Solution for Fully Automatic Paving Brick Concrete Batching Plant

Paving Brick Dedicated Concrete Batching Plant: Equipped with Planetary Mixer for High-Strength, High-Quality Paving Bricks

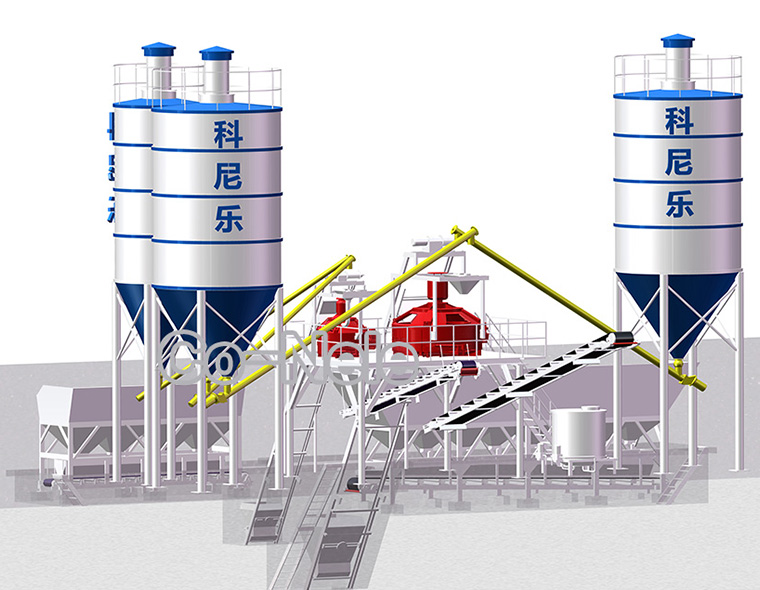

The demand for higher quality, efficiency, and environmental performance of paving bricks has increased. Therefore, we introduce a paving brick concrete batching plant featuring a core planetary concrete mixer. This integrated solution is designed for large-scale, high-standard production of paving bricks (such as permeable bricks, grass pavers, plaza bricks, and curb stones), achieving full automation and superior performance from material metering and efficient mixing to discharge.

Core Equipment Configuration_Professional Pavement Brick Concrete Batching Plant Solution:

This production line is built through a strong collaboration between Fujian Quanzhou High-Performance Fully Automatic Hydraulic Brick Making Machine and CO-NELE professional concrete mixing equipment, specifically designed for large-scale production of high-quality paving bricks, permeable bricks, grass pavers, and curb stones.

| Device type |

Brand/Model |

Key Performance and Features |

Role in the production line |

| Planetary concrete mixer (for base materials) |

CO-NELE / CMP2000 |

- High-Capacity Powerful Mixer: Rated discharge capacity of 2000 liters, mixing power of 75KW, and a production rate of up to 120 m³/h.

- High Uniformity: The planetary mixing principle ensures extremely uniform mixing of dry-hard concrete.

- Professional Application: Suitable for mixing dry-hard concrete required for paving bricks and high-performance concrete (UHPC) and other demanding materials.

|

Main Pavement Brick Concrete Batching Plant: Responsible for high-capacity, efficient, and homogeneous mixing of the main concrete base materials for the production line. |

| Planetary high-speed mixer (for fabrics) |

CO-NELE/CMPS500 |

- Fast and precise: Rated discharge capacity of 500 liters, working cycle as short as 60 seconds, mixing power of 18.5KW.

- Flexible and efficient: Designed for quick changeover and mixing of colored fabrics and special surface materials (such as those with added pigments and reinforcing agents).

|

Fabric-specific machinery: Ensures rapid mixing and uniform color of the colored surface layer material, and efficient integration with the base material, enabling the production of colored tiles. |

| Fully Automatic Hydraulic Brick Making Machine |

Quangong / Model 18 Series |

- High production capacity: Can produce up to 25,600 standard bricks in 8 hours.

- Multi-functional: Can produce various concrete blocks, paving bricks, grass pavers, etc.

|

Molding core: Receives the mixed concrete and, through hydraulic vibration and pressure, molds it into high-density, high-strength paving brick products. |

Pavement Brick Concrete Batching Plant Integrated System Advantages

This \”dual planetary mixer + Quanzhou brick machine\” combination offers four core advantages compared to single-machine operation or ordinary combinations:

Maximized Production Efficiency

- Clear division of labor, no waiting: The CMP2000 ensures a continuous and stable supply of base material, while the CMPS500 focuses on rapid preparation of face material, allowing the brick machine to operate at full capacity continuously.

- Significantly increased output: Professionally matched equipment avoids production bottlenecks caused by insufficient mixing capacity or mismatched speeds.

Excellent Product Quality

- Top-notch mixing effect: Two planetary mixers are optimized for the characteristics of the base and face materials respectively, ensuring that the materials from inside to outside achieve the highest uniformity, which is fundamental to the high strength, high wear resistance, and consistent color of the bricks.

- Stable and reliable molding: The stable hydraulic and vibration system of the Quanzhou brick machine ensures dense molding of highly uniform concrete under high pressure.

High Production Flexibility

Easily handles the production of colored bricks, composite layer bricks, and functional bricks (such as permeable bricks). The face material mixer can quickly switch between different formulas to meet the needs of small-batch, multi-variety orders.

Reliable Return on Investment

- Low failure rate: The core equipment comes from established brands with stable performance and high durability.

- Easy maintenance: The modular design, coupled with technical support and spare parts supply from the manufacturer, minimizes downtime.

Previous: Misturador de Concreto Planetário CMP1000

Next: Concrete Batching Plant for Road Bricks