The planetary concrete mixer’s mixing action produces quality homogenised mixes.CONELE focuses on manufacturing the better mixers and relative accessories for concrete, refractory, ceramic, glass, foundry and metallurgy industries.We have gained over 80 national patents. High uniformity and maneuverability in producing concrete mixtures are the demand of concrete producers all around the world.

Our CMP planetary concrete mixers are devices that offer a reliable solution to make this possible. Our planetary mixers provide high-quality mixing of all types of concrete like precast concrete, ready-mix concrete, fiber-reinforced, self-compacting concrete and other aggregates.

Frequently Asked Questions

1.Are you trading company or Manufacturer?

A: We are Manufacturer.We have been engaged in the production of planetary concrete mixer for more than 20 years.CONELE is the largest exporter of planetary mixer in China.

2.How does the planetary concrete mixer work?

A: The planetary concrete mixer adopts the principle of planetary mixing, and combines the rotation and revolution mode, which provides forcing effects such as extrusion and overturning on the material during the operation of the equipment.

3.How to choose the suitable model of planetary concrete mixer?

A: Just tell us the capacity (m3/h,t/h)of concrete you want to produce concrete per hour or per month.

4.What is the price of the planetary concrete mixer?

A: The planetary concrete mixer is obviously affected by factors such as equipment specifications, technical design costs, and the comprehensive market environment. These are also important factors that affect the price gap between different vertical shaft planetary mixer manufacturers. If you want to know the price, you can click the button to send an inquiry or contact us directly.

Specifications

| Item |

CMP1000

|

| Output capacity(L) |

1000

|

| Input capacity(L) |

1500

|

| Output weight(Kg) |

2400

|

| Mixing power(Kw) |

37

|

| Discharging power(Kw) |

3

|

| Planet/mixing arm |

2/4

|

| Paddle(nr) |

1

|

| Discharging paddle(nr) |

1

|

| Weight(Kg) |

6200

|

| Lifting power(Kw) |

11

|

| Dimension(L×W×H,mm) |

2890×2602×2220

|

Why Choose Us

Our company is located in Qingdao city Shandong Province and our factory has two manufacturing bases. The plant construction area of 30,000 square meters. We provide high quality products throughout the country and also exports to more than 80 countries and regions from Germany, United States, Brazil,South Africa etc.

We have our own professionals and technicians to handle evelopment, design, production, sales and service.Our products have passed the CE certification and obtained ISO9001,ISO14001,ISO45001 system ertification.Planetary mixer has the first domestic market share.We have A-level unit of Mixing Machine Research Institute.

We have more than 50 technician to ensure superior installations and after sale service to assist customer to install the machine and perfrom the proper training abroad.

Advantages

1.Gearing system

Driving system consists of motor and hardened surface gear which is specialized designed by CO-NELE (patented).Flexible coupling and hydraulic coupling (option) connects motor and gearbox.

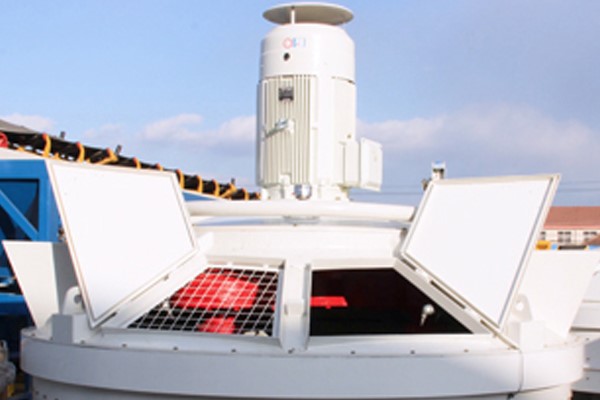

2. Mixing device

Compulsory mixing is realized by composite moves of extruding and overturning driven by rotating planets and blades.

3.The hydraulic power unit

A special designed hydraulic power unit is used to provide power for more than one discharging gates.On emergency,these discharging gates can be opened by hand.

4.Discharging door

The number of the discharging door is three at most. And there is special sealing device on the discharging door to ensure the sealing reliable.

5.Water device

Overhead structure is used to water(patent products).The nozzle which adopts spiral solid cone nozzle,has a fine uniformatomization effect,large covering area and make the material more uniform mixing.

6.Discharging device

According to the different demands of customers, the discharging door can be opened by hydraulic, pneumatic or by hands.

Previous: UHPC mixer for CMP500 planetary concrete mixer

Next: Laboratory Refractory Mixer