CO-NELE Machinery Co., Ltd.

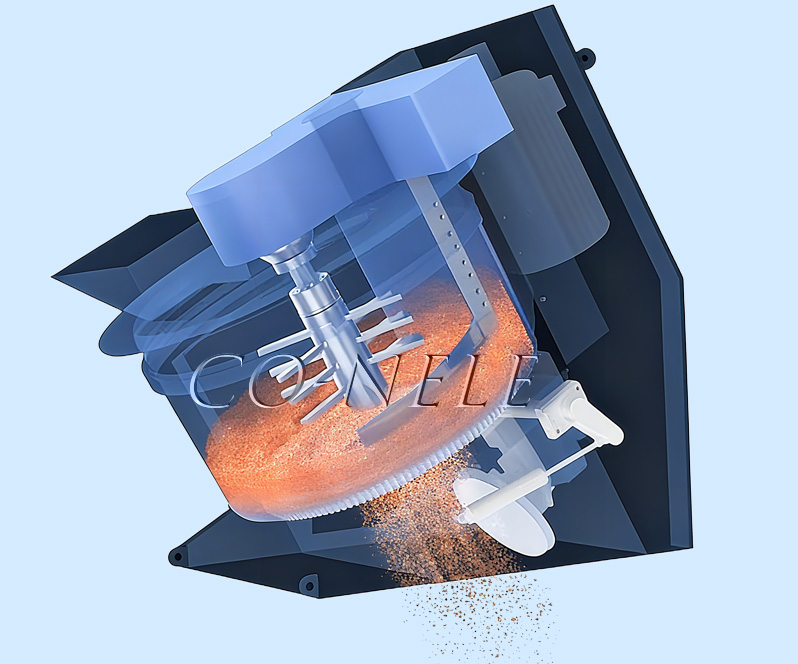

Intensive mixers manufactured by co-nele Machinery adopt the counter-current or cross-flow design principle, making the material processing more efficient and uniform. During the material preparation process, it achieves more diverse characteristics of material mixing direction and intensity. The interaction between the mixing and counter-mixing forces enhances the mixing effect, ensuring that a stable mixed material quality is achieved in a short time. Kneader Machinery has rich experience in the field of mixing and stirring and can meet the high-quality mixing needs of different industries.

CO-NELE Machinery has always been positioned in the mid-to-high-end segment of the industry in terms of product positioning, providing support for production lines in various domestic and foreign industries, as well as high-end customization and new material experimental applications and other fields.

Intensive Mixers Core technological advantages

The new concept of "three-dimensional mixed granulation technology with reverse or cross-flow"

01

Particles are evenly distributed.

High balling rate, uniform particle size, high strength

06

Meet the requirements of each department

The application scope is wide, and it can meet the blending requirements of different industries and various materials.

02

The process can be preset.

The mixing granulation process can be preset and can also be adjusted during the production process.

Environmental protection

The entire process of mixed granulation is carried out in a fully enclosed manner, without any dust pollution, ensuring safety and environmental protection.

03

Controllable particle size

The rotating mixing cylinder and the granulation tool set can be controlled by variable frequency. The rotational speed can be adjusted, and the particle size can be controlled by adjusting the speed.

08

Heating / Vacuum

Heating and vacuum functions can be added according to user requirements

04

Easy unloading

The unloading method can be either tilting unloading or bottom unloading (controlled by hydraulic system), which is quick and clean with easy cleaning.

09

Visual control system

Equipped with an independent control cabinet, it can be connected to the PLC control system to achieve fully automatic control.

A wide range of models

We offer a complete range of models, covering everything from small laboratory granulation to large-scale industrial balling, and can meet all your needs.

CO-NELE has been dedicated to the process of mixing and granulation for 20 years.

CO-NELE Machinery Equipment Co., Ltd. was established in 2004. It is a high-tech enterprise specializing in the research, development, manufacturing and sales of mixing, granulation and molding equipment. The company's products cover a full range of mixing and granulation equipment, and it also provides management consulting services, technical improvement, talent training and other related services for the industry.

Create a new legend in industrial mixture preparation and granulation technology, starting with CO-NELE!

Turbulent three-dimensional mixing granulation technology

CO-NELE applies its unique three-dimensional turbulent mixing granulation technology, which saves at least three times more time compared to other granulation machines on the market!

Counter-current three-dimensional mixing granulation technology: It can achieve the processes of mixing, kneading, pelletizing and granulation within the same equipment, and ensure that the mixed materials are fully and evenly distributed.

The process is simple and straightforward, and it enables the rapid and efficient production of the required particles within the shortest possible time.

Countercurrent Three-Dimensional Mixing Granulation Technology - Creating Industry Leadership Brands

The unique mixing principle ensures that 100% of the materials are involved in the mixing process, achieving the best product quality within the shortest mixing time, suitable for batch operations.

While the mixing device is rotating at high speed, the cylinder is driven to rotate by the reducer, and the mixing cylinder is inclined at a certain angle to achieve a three-dimensional mixing mode, which makes the materials flip more vigorously and the mixture more uniform.

The CR mixer can be designed based on the cross-flow principle or the countercurrent principle, and the mixing direction can be either forward or reverse.

Higher mixing tool speeds can be utilized

Better fiber decomposition

Complete grinding of pigments

Optimal mixing of fine materials

Production of high-solid-content suspensions

Moderate-speed mixing will result in a high-quality mixture.

During low-speed mixing, lightweight additives or foams can be gently added to the mixture.

During the mixing process of the mixer, the materials will not be separated. Because each time the mixing container rotates,

100% of the materials are involved in the mixing.

Compared with other mixed systems, the CO--NELE batch-type powerful mixer of Konil offers the ability to independently adjust both the output and the mixing intensity:

The rotational speed of the mixing tool can be adjusted from fast to slow at will.

The setting for inputting mixed energy for mixed products is available.

It can achieve an alternating hybrid process, such as: slow – fast – slow

Higher mixing tool speeds can be used for:

The optimal dispersion of fibers

The complete grinding of pigments, achieving the best mixing of fine materials

The production of high-solid-content suspensions

Moderate-speed mixing will result in a high-quality mixture.

During low-speed mixing, lightweight additives or foams can be gently added to the mixture.

During the mixing process of the mixer, the materials will not be separated. Because each time the mixing container rotates, 100% of the materials are involved in the mixing.

The Konile CO-NELE batch-type mixer has two series, with the capacity ranging from 1 liter to 12,000 liters.

Compared with other mixed systems, the CO-NELE continuous mixing machine produced by Konil offers the ability to independently adjust both the output and the mixing intensity.

Different rotational speeds of the mixing tools

Different rotational speeds of the mixing container

Adjustable and accurate material retention time during the mixing process

The entire mixing process was extremely perfect. Even at the initial stage of the mixing, it was ensured that there would be no situation where the materials did not mix or only partially mixed before leaving the mixing machine.

The Konil powerful mixer can also be designed accordingly, enabling it to operate under vacuum/heat/cool conditions.

The vacuum/heat/cooling mixer series not only retains all the advantages of the powerful mixer, but also, based on its application in different industries,

additional process technical steps can also be completed in the same equipment, such as:

Exhaust

Dryness

Cooling or

Cooling during the reaction at a specific temperature

Application of technology

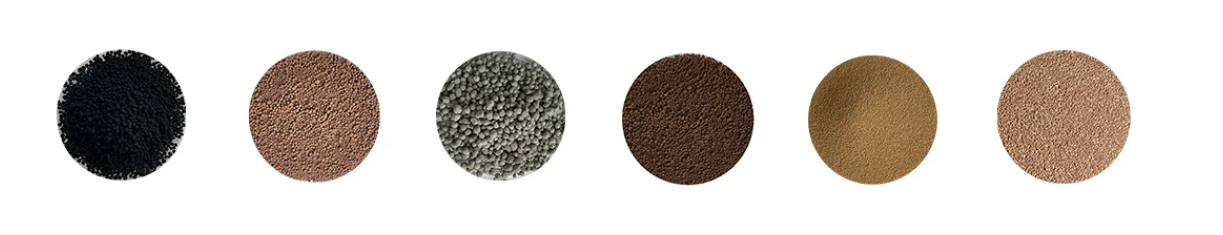

Molding sand

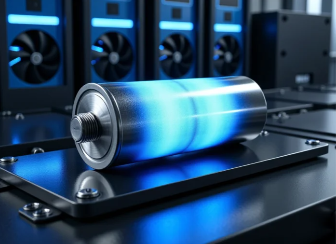

Battery lead paste

High-density particles

Sludge containing water or solvents

Metal-containing sludge

Friction pad

Soap

The operating capacity of the vacuum mixer ranges from 1 liter to 7000 liters.

Model of the mixed granulation machine

Lab Intensive Mixer- Professional, quality builds brand

Flexible

Provide the leading laboratory type granulator in the country

Diversity

We can provide customers with laboratory equipment and conduct thorough mixing tests for different materials.

Convenience

Possessing unique professional skills and rich experience in manufacturing, debugging and mixed granulation

CO-NELE Intensive mixer can achieve a production output of over 100 tons per hour, and it can also meet the needs of various research institutions, universities and enterprises for one-liter-scale mixing and granulation experiments in the laboratory! For professional mixing and granulation, choose conele!

Industry application

Metallurgy

Fire-resistant materials

Ceramics

Preparation of lead-acid lithium batteries

Engineering Case

Inclined intensive mixer for magnesium-carbon bricks

Intensive mixer is used in the production of honeycomb zeolite.

CR intensive mixer is applied to 3D sand printing.

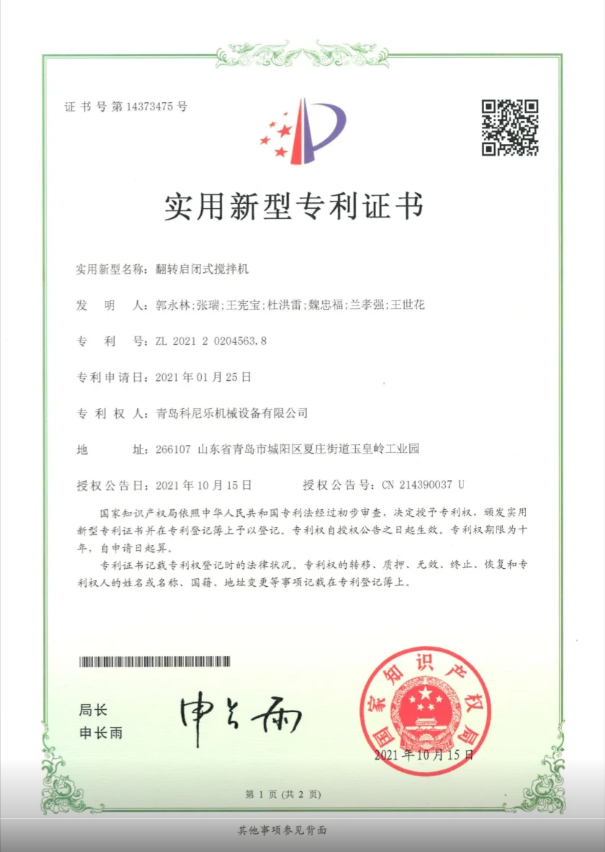

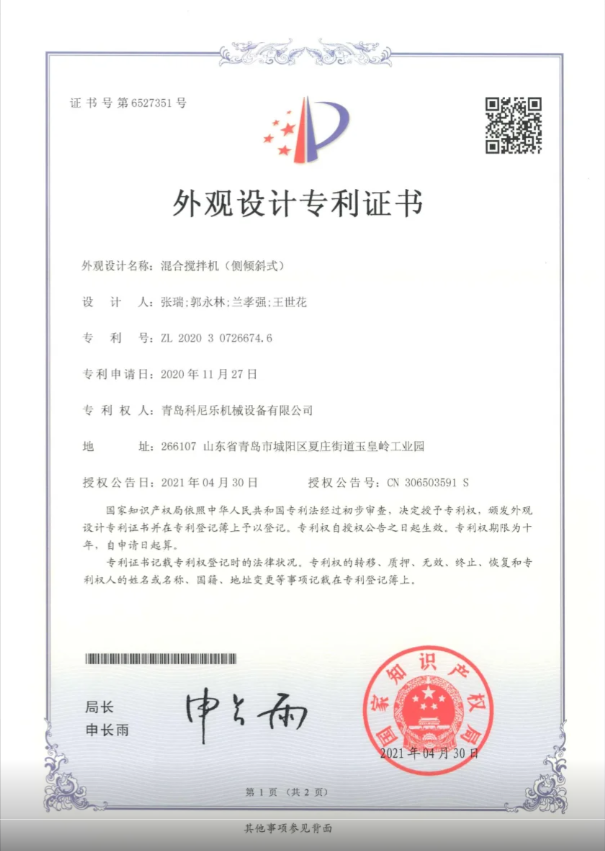

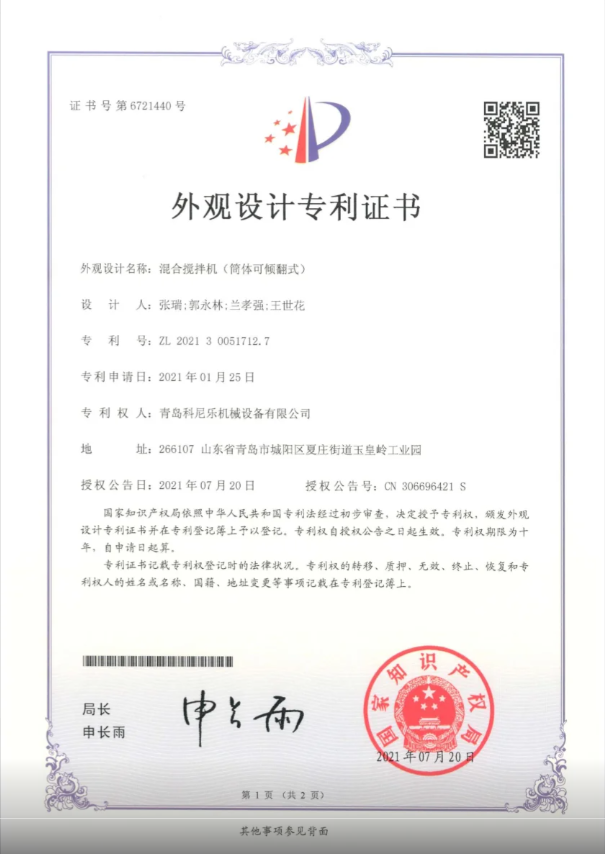

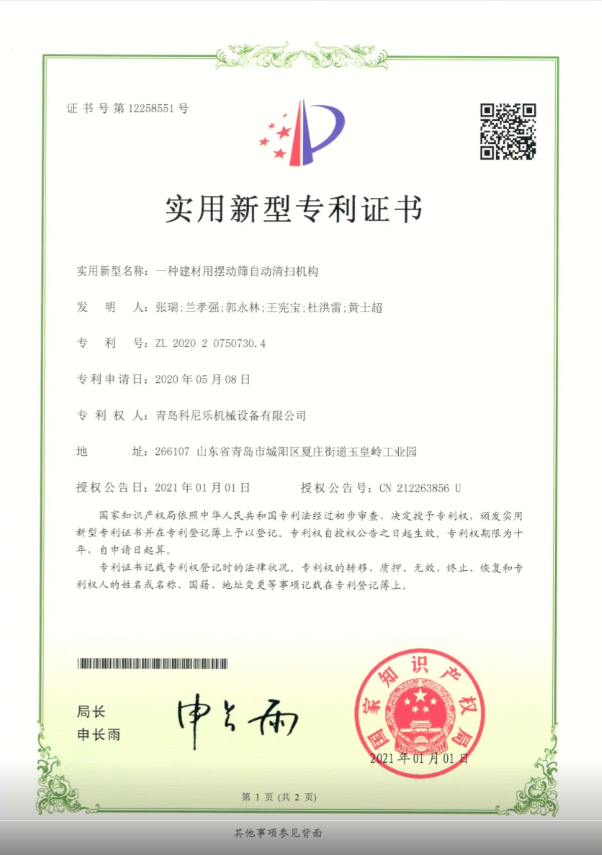

Patent report, with high standards, ensuring peace of mind

CO-NELE's entire design

CONELE has a professional design service team. From the design and integration of single equipment to the design and installation of entire production lines, we can provide our clients with perfect solutions.