As a professional mixing equipment manufacturer, Qingdao CO-NELE Machinery’s HZS25 concrete batching plant combines advanced technology with practical functions. Featuring a modular design, it boasts a theoretical production rate of 25m³/h²

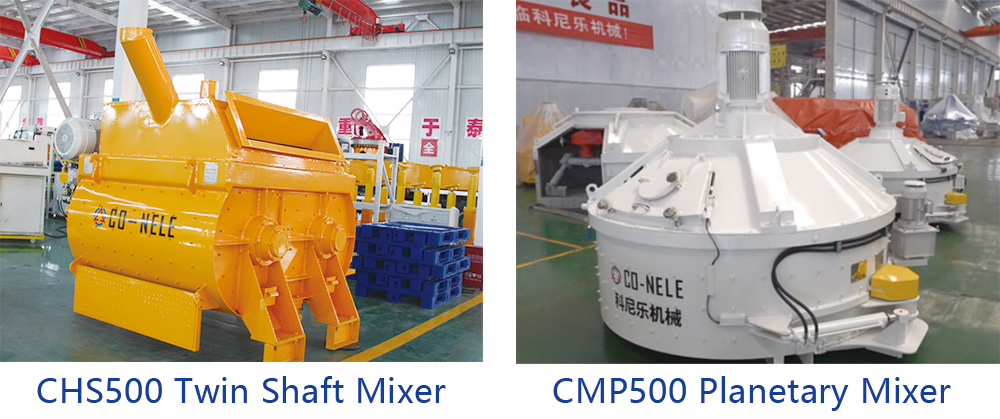

This plant can be configured with either a CMP500 vertical-shaft planetary mixer or a CHS500 twin-shaft mixer to meet mixing requirements in various operating conditions. It is widely used in precast plants, highway and bridge projects, and water conservancy and hydropower construction.

Core Structure of a Concrete Batching Plant

The co-nele HZS25 concrete batching plant consists of four core systems, each meticulously designed and manufactured to ensure efficient and stable operation:

1. Mixing System

The HZS25 concrete batching plant is available with two optional mixing units:

CHS500 Twin-Shaft Compulsory Mixer: This unit utilizes two counter-rotating mixing shafts mounted within a U-shaped mixing drum, equipped with multiple mixing tools. This design utilizes shearing, turning, and impacting forces to create a circular motion within the mixer, effectively releasing energy and quickly achieving a uniform mix.

The unit utilizes a highly wear-resistant alloy mixing arm, offering strong impact resistance and preventing breakage. It also utilizes hydraulic discharge for clean, fast discharge. It utilizes a fully automatic lubrication system with independent oil pumps for reliable performance and consistent lubrication.

CMP500 Vertical Shaft Planetary Mixer: This unit utilizes planetary shafts rotating and revolving within the drum, generating a powerful mixing motion that rapidly displaces material within the drum, covering a wide area. The drum is equipped with a multifunctional tool to quickly scrape material from the drum walls and bottom, achieving high uniformity within the drum. It is suitable for high-quality concrete (dry, semi-dry, and plastic concrete) and achieves high homogeneity in the shortest possible time.

2.Batching System

The PLD1200 concrete batcher features an aggregate hopper with a capacity of 2.2-6m³. It utilizes a “pin”-shaped feeding mechanism and lever-type single-sensor weighing technology, with a batching capacity of 1200L.

The batching system utilizes electronic scales for metering, with aggregates metered separately to ensure precise mix ratios. The combination of the batcher and mixer forms a simple concrete mixing station, fully leveraging the advantages of both.

3.Conveying System

The Professional-Grade 25m³/h Concrete Batching Plant – CO-NELE’s Efficient Mixing Solutionsoffers two optional loading methods:

Belt conveyor: Capacity reaches 40 tons/hour, suitable for continuous production.

Bucket loading: Suitable for sites with limited space.

Powder conveying uses a screw conveyor, with a maximum capacity of 3.8 m³/hour. The conveying system is rationally designed, operating smoothly, with low noise, and easy maintenance.

4.Weighing and Control System

The weighing system utilizes independent metering, measuring each material separately to ensure a precise mix ratio.

Aggregate weighing accuracy: ±2%

Powder weighing accuracy: ±1%

Water weighing accuracy: ±1%

Additive weighing accuracy: ±1%

The control system utilizes a centralized microcomputer for simple operation, easy adjustment, and reliable performance. High-quality electrical components (such as Siemens) ensure reliable performance.

The system supports both automatic and manual operation and is equipped with a dynamic display panel and data storage, enabling precise weighing of sand, gravel, cement, water, and additives.

Professional-Grade 25m³/h Concrete Batching Plant – CO-NELE’s Efficient Mixing Solutions

| parameter |

Technical indicators |

unit |

| Theoretical production capacity |

25 |

m³/h |

| Mixers |

CHS500 Twin shaft mixer or CMP500 Planetary Mixer |

- |

| Discharge Capacity |

0.5 |

m³ |

| Feed Capacity |

0.75 |

m³ |

| Mixing Power |

18.5 |

Kw |

| Maximum Aggregate Size |

40-80 |

mm |

| Duration |

60-72 |

S |

| Water Weighing Range |

0-300 |

Kg |

| Air Compressor Power |

4 |

Kw |

The co-nele HZS25 concrete batching plant offers the following significant advantages:

High-efficiency mixing performance: Utilizing a forced mixing principle, it achieves short mixing times, rapid discharging, uniform mixing, and high productivity, producing highly plastic, high-dry-hard concrete with reliable quality.

Precise metering system: Utilizing independent metering, each material is metered separately to ensure accurate mix ratios. Weighing accuracy is high: ±2% for aggregates, ±1% for powders, and ±1% for water and additives.

Modular design: Its modular construction shortens installation time to 5-7 days, reducing relocation and reconstruction costs by 40%. It features convenient installation and simplified maintenance.

Environmentally friendly and low-noise: Utilizing a pulse electric dust removal device and noise reduction design, operating noise levels are 15% lower than the industry average.

High reliability: The main unit utilizes a multi-layer sealing structure combining a floating oil ring, specialized seals, and mechanical seals to effectively prevent friction between the mixture and the shaft, eliminating slurry leakage.

The CO-NELE HZS25 concrete batching plant is suitable for a variety of applications:

Precast component production: Suitable for all types of large and medium-sized precast component plants

Construction projects: Industrial and civil construction projects such as roads, bridges, water conservancy projects, and docks

Special projects: Field construction projects such as railways and hydropower projects

Multi-material mixing: Suitable for mixing dry hard concrete, lightweight aggregate concrete, and various mortars

Configuration expansion options

Optional additional devices can be added to meet project requirements:

Admixture metering system: Accuracy of ±1%, independent control unit

Dry-mix mortar storage tank: Can be equipped with a 30-ton standard capacity

Mobile chassis: Compatible with the PLD800 batching machine for rapid site transfer

Winter construction kit: Includes aggregate preheating and water temperature control system

About co-nele

The HZS25 concrete batching plant manufactured by Qingdao Co-nele Machinery Co., Ltd. combines advanced technology with practical functions. Its excellent mixing performance, precise metering system, and reliable operation make it an ideal choice for small and medium-sized construction projects.

Whether equipped with the CHS500 twin-shaft mixer or the CMP500 vertical-shaft planetary mixer, both can meet users’ high demands for concrete quality and production efficiency, and are reliable mixing solutions for various construction projects.

Previous: Glass Industry Batch mixer

Next: UHPC Batching Plant for Concrete towers