Bear "Customer first, High quality first" in mind, we perform closely with our consumers and provide them with efficient and experienced services for Concrete Mixer Cement Mixer , Mobile Mortar Mixer , Pizza Dough Mixer , Our professional technical team will be wholeheartedly at your service. We sincerely welcome you to visit our website and company and send us your inquiry.

Refractory Paddle Mixer Manufacturer – 30m3/h Mobile concrete batching plant MBP08 – CO-NELE Machinery Detail:

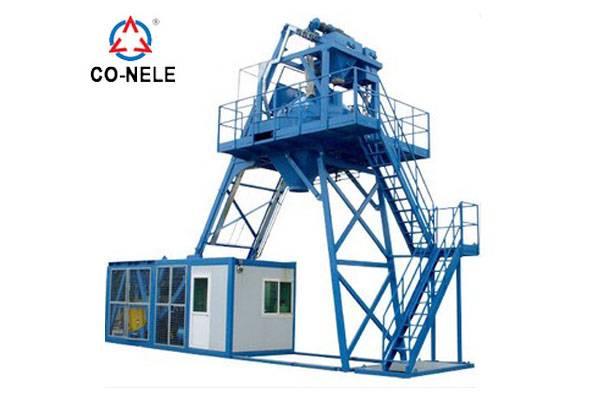

30m3/h Mobile Concrete Batching Plant which is the smallest capacity concrete plant of CO-NELE Mobile Concrete Batching Plant Series can be equipped with either 750l planetary concrete mixer or twin shaft concrete mixer. provides 30 m³/h vibrated concrete production capacity.

CO-NELE mobile concrete plant is very suitable for short term or medium term projects to produce plastic concrete, dry hard concrete, etc. provides the following advantages to its users:

- Quick and easy installation (only 1 day)

- Cost-effective transportation (the main unit can be transported by one truck trailer)

- Due to the special design, it can be installed on a confined space

- Quick and easy jobsite relocation

- Low foundation cost (installation on a flat concrete surface)

- Minimizes the concrete transportation cost and environmental impact as well

- Easy maintenance and low operating cost

- High production performance with optimized automation system

To get more details about the advanced manufacturing technology and the components of CO-NELE Concrete Batching Plants, please visit our Why Should I Prefer CO-NELE?

fter realizing the growing need for mobility and flexibility day by day in the concrete and construction sector, CO-NELE has designed and produced the first mobile concrete batching plant in China 20 years ago. Until now, from Canada to Germany, from England to South Africa, more than 1000 units of CO-NELE mobile concrete batching plants were installed in more than 100 countries carry on concrete production in important projects.

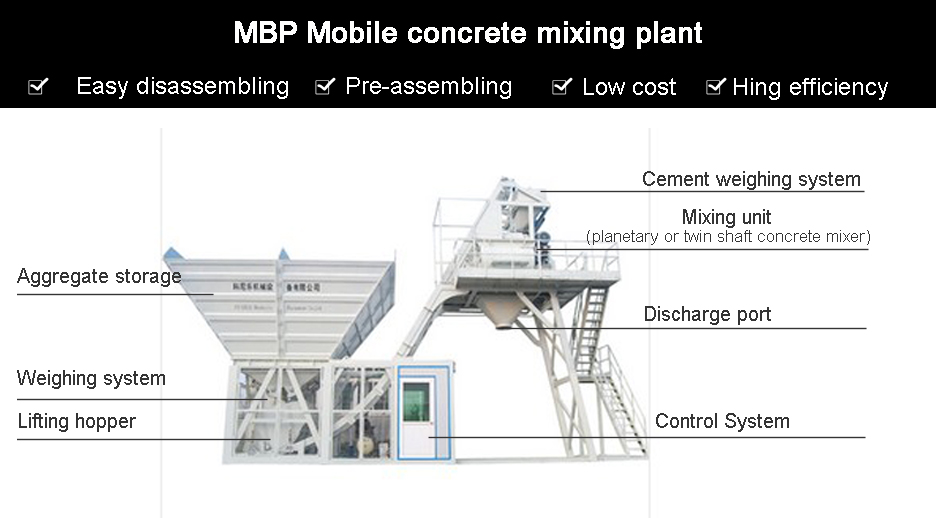

Mobile batching plant consists of the following components

Mixing platform, concrete mixer, aggregate storage hopper, aggregate weighing system, aggregate skip hoist, water weighing system, cement weighing system, control cabin and so on. All components connect each other to form independent equipment.

| Item |

Type |

| MBP08 |

MBP10 |

MBP15 |

MBP20 |

| Output(theoretical) |

m3/h |

30 |

40 |

60 |

80 |

| Discharging Height |

mm |

4000 |

4000 |

4000 |

4000 |

| Mixer Unit |

Dry filling |

L |

1125 |

1500 |

2250 |

3000 |

| Output |

L |

750 |

1000 |

1500 |

2000 |

| Mixing power |

kw |

30 |

37 |

30*2 |

37*2 |

| weighing and feeder skip |

Drive power |

kw |

11 |

18.5 |

22 |

37 |

| Medium speed |

m/s |

0.5 |

0.5 |

0.5 |

0.5 |

| Capacity |

L |

1125 |

1500 |

2250 |

3000 |

| Weighing precision |

% |

±2 |

±2 |

±2 |

±2 |

| Cement weighing system |

Capacity |

L |

325 |

425 |

625 |

850 |

| Weighing precision |

% |

±1 |

±1 |

±1 |

±1 |

| Liquid weighing systemS |

Capacity |

L |

165 |

220 |

330 |

440 |

| Water weighing precision |

% |

±1 |

±1 |

±1 |

±1 |

| Admixture weighing precision |

% |

±2 |

±2 |

±2 |

±2 |

| Cement screw conveyor |

External |

mm |

Φ168 |

Φ219 |

Φ219 |

Φ273 |

| Speed |

t/h |

20 |

35 |

35 |

60 |

| Power |

kw |

5.5 |

7.5 |

7.5 |

11 |

| Control mode |

|

Automatic |

Automatic |

Automatic |

Automatic |

| Power |

kw |

53 |

69 |

97 |

129 |

| Weight |

T |

15 |

18 |

22 |

30 |

Mobile concrete mixing plant transport state

Product detail pictures:

Related Product Guide:

The Advancement of Concrete Mixer Through the Years

All About Concrete Mixer

Dependable good quality and very good credit score standing are our principles, which will help us at a top-ranking position. Adhering towards the tenet of "quality initial, shopper supreme" for Refractory Paddle Mixer Manufacturer – 30m3/h Mobile concrete batching plant MBP08 – CO-NELE Machinery, The product will supply to all over the world, such as: Madagascar, Hyderabad, Rwanda, By integrating manufacturing with foreign trade sectors, we can offer total customer solutions by guaranteeing the delivery of right items to the right place at the right time, which is supported by our abundant experiences, powerful production capability, consistent quality, diversified product portfolios and the control of the industry trend as well as our mature before and after sales services. We'd like to share our ideas with you and welcome your comments and questions.