We now have several exceptional workers customers good at marketing, QC, and working with types of troublesome trouble during the creation system for twin shaft concrete mixer suppliers , Mini Mobile Concrete Batching Plant For Sale , Clc Mixer For Cast-in-situ , We welcome shoppers, business enterprise associations and close friends from all sections with the globe to contact us and seek cooperation for mutual added benefits.

China Concrete Mixer Plant – CHS Twin shaft concrete mixer – CO-NELE Machinery Detail:

Professional bucket double shaft 1000L concrete mixer,

1000l Concrete Mixer, double shaft 1000L concrete mixer,

Technical data

| Model |

CHS750 |

CHS1000 |

CHS1250 |

CHS1500 |

CHS2000 |

CHS2500 |

CHS3000 |

CHS3500 |

CHS4000 |

CHS4500 |

CHS5000 |

CHS6000 |

| In capacity(L) |

1125 |

1500 |

1875 |

2250 |

3000 |

3750 |

4500 |

5250 |

6000 |

6750 |

7500 |

9000 |

| In mass(Kg) |

1800 |

2400 |

3000 |

3600 |

4800 |

6000 |

7200 |

7200 |

9600 |

10800 |

12000 |

14400 |

| Out capacity(L) |

750 |

1000 |

1250 |

1500 |

2000 |

2500 |

3000 |

3500 |

4000 |

4500 |

5000 |

6000 |

| Paddles nunber |

2×5 |

2×6 |

2×6 |

2×7 |

2×7 |

2×8 |

2×9 |

2×9 |

2×10 |

2×10 |

2×10 |

2×11 |

| Motor power(Kw) |

30 |

37 |

45 |

55 |

37×2 |

45×2 |

55×2 |

65×2 |

75×2 |

75×2 |

90×2 |

110×2 |

| Discharging power(Kw) |

3 |

3 |

3 |

3 |

3 |

3 |

4 |

4 |

4 |

4 |

4 |

4 |

| Weight(Kg) |

4500 |

5000 |

5500 |

6000 |

8400 |

9000 |

9500 |

9500 |

13000 |

14500 |

16500 |

19000 |

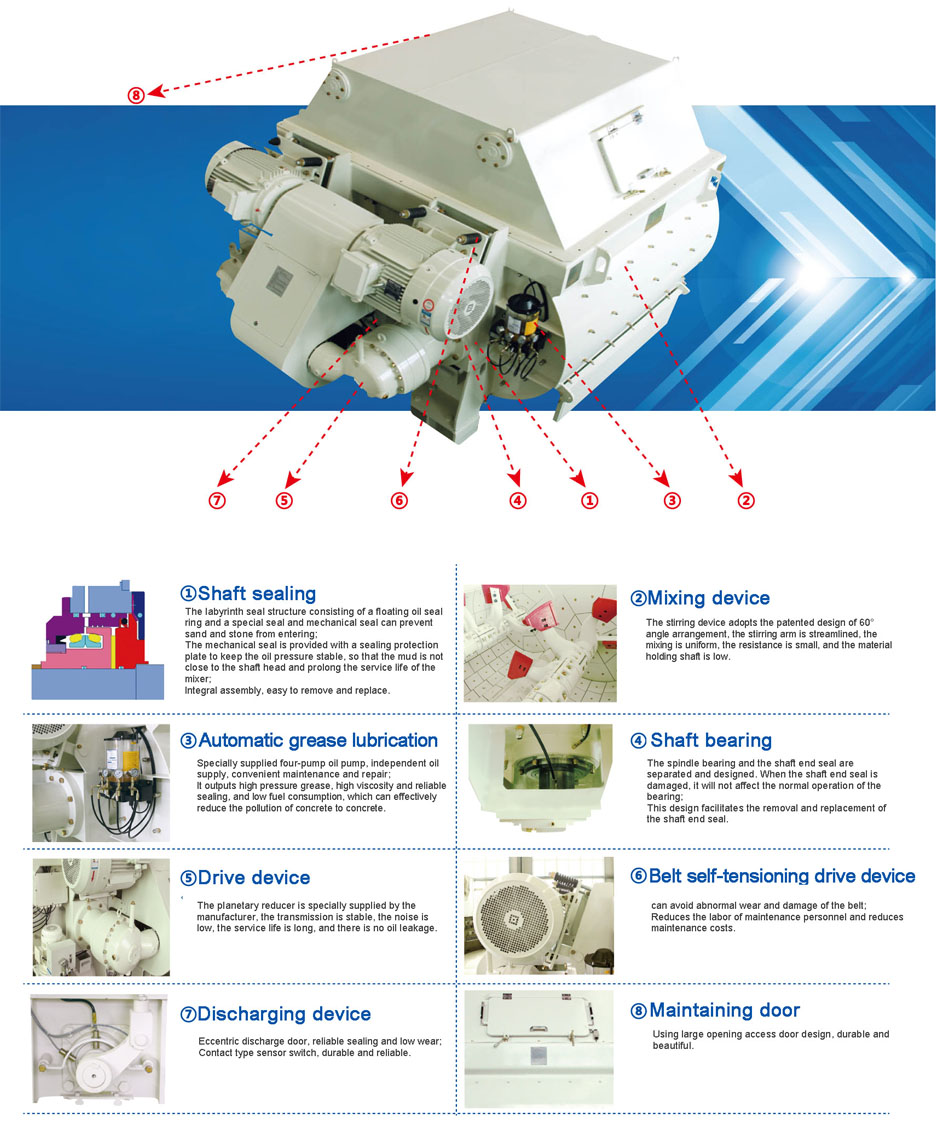

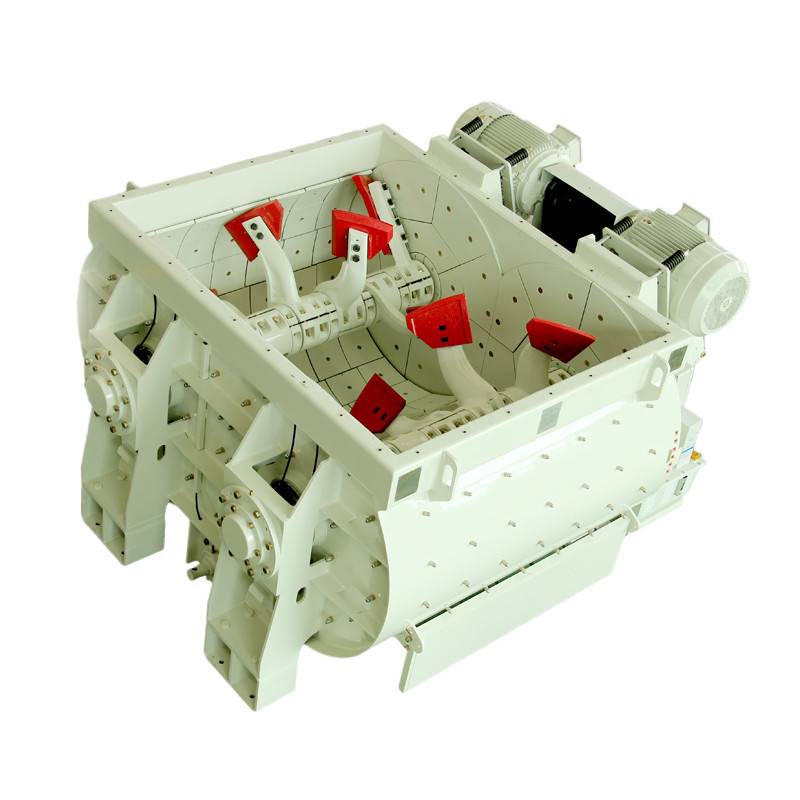

Product Introduction

CO-NELE concrete mixer is designed compactly overall. All parts are installed in the mixing drum with small space occupation, making it easy to install and update the whole machine.

1000 liters twin shaft concrete mixer

CO-NELE TWIN-SHAFT MIXER ADVANTAGES

1)The shaft end seal is equipped with a floating oil seal ring, a special labyrinth seal structure composed of a seal and a mechanical seal, which has reliable sealing, high stability and long service life;

2) automatic lubrication system configuration, four independent oil pump, high working pressure, excellent performance;

3) On-mounted motor installation layout, patented belt self-tensioning device to improve transmission efficiency, to avoid excessive wear and damage to the belt, reduce maintenance costs,The large volume ratio design concept is adopted for the helium cylinder, which can effectively improve the mixing efficiency, prolong the service life of the shaft end seal, and reduce the probability of material shaft holding;

4) Discharging door adopts eccentric double sealing design to prevent material jamming and leakage, small wear, high sealing efficiency and long-lasting;

5) Stirring device adopts a patented design with an angle of 60°. Flow line casting of the stirring arm results in uniform mixing, low resistance, and low rate of material holding shaft;

6)Configured with military-grade planetary speed reducers with smooth transmission and high load capacity;

7) Optional original Italian reducer, original German automatic lubrication pump, high pressure cleaning device, temperature and humidity testing system;

Product detail pictures:

Related Product Guide:

All About Concrete Mixer

Choosing the Best Concrete Mixer for the Job

The key to our success is "Good Product Excellent, Reasonable Rate and Efficient Service" for China Concrete Mixer Plant – CHS Twin shaft concrete mixer – CO-NELE Machinery, The product will supply to all over the world, such as: Marseille, New Delhi, Greece, We maintain long-term efforts and self-criticism, which helps us and improvement constantly. We strive to improve customer efficiency to save costs for customers. We do our best to improve the quality of product. We will not live up to the historic opportunity of the times.