Ukuze uqinisekise ukuthi i-concrete twin-shaft mixer ingasetshenziswa kangcono, yandise impilo yesevisi ngangokunokwenzeka, futhi idale izinzuzo ezengeziwe zomnotho kuwe, sicela unake izinto ezilandelayo uma usebenzisa. Sicela uhlole ukuthi izinga likawoyela le-reducer kanye ne-hydraulic pump liyafaneleka yini ngaphambi kokusetshenziswa kokuqala. Izinga likawoyela le-reducer kufanele libe phakathi kwesibuko sikawoyela. I-hydraulic oil pump kufanele igcwaliswe uphethiloli ku-oyela gauge 2 (uwoyela ungase ulahleke ngenxa yokuhamba noma ezinye izizathu). Hlola kanye ngesonto kamuva. Isinyathelo sokuxuba siqalwa kuqala ngemva kokuxuba, akuvunyelwe ukuqala ngemva kokuphakela, noma ukuphakela okuphindaphindiwe, ngaphandle kwalokho kuzoholela emshinini oyisicefe, okuthinta ukusebenza kanye nempilo yesevisi ye-mixer. Ngemva kokuqedwa komjikelezo ngamunye wokusebenza we-mixer, ingaphakathi lesilinda kumele lihlanzwe kahle, okuzothuthukisa impilo ye-mixer ngempumelelo futhi kunciphise ukusetshenziswa kwamandla.

Ukugcinwa kokuphela komgodi

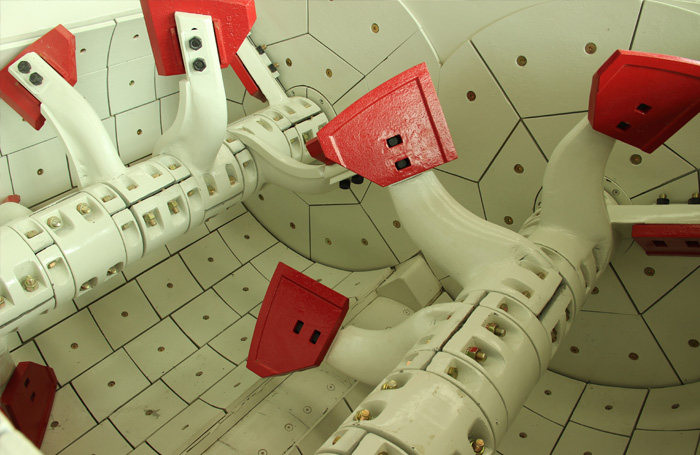

Isivalo sokugcina umgodi siyindawo ebaluleke kakhulu yokugcinwa komshini wokuxuba. Indlu yekhanda lomgodi (indawo yokufaka uwoyela wepompo kawoyela) iyisakhi esiyinhloko sesivalo sokugcina umgodi. Kuyadingeka ukuhlola ipompo kawoyela wokugcoba ukuze ibone ukuthi uwoyela uvamile yini nsuku zonke.

1, Isilinganiso sokucindezela esinokuboniswa kwengcindezi noma esingenaso

2. Ingabe kukhona uwoyela enkomishini kawoyela yepompo kawoyela?

3, Kungakhathaliseki ukuthi ikhatriji yephampu ijwayelekile noma cha

Uma kutholakala iphutha, kuyadingeka ukumisa ukuhlolwa ngokushesha bese uqhubeka nokusebenza ngemva kokuxazulula inkinga. Ngaphandle kwalokho, kuzobangela ukuthi ingxenye yomshafti ivuze futhi kuthinte umkhiqizo. Uma isikhathi sokwakha sincane futhi singenakulungiseka ngesikhathi, kungasetshenziswa uwoyela wesandla.

Njalo ngemizuzu engama-30. Kuyadingeka ukugcina uwoyela wokugcoba ngaphakathi kokuphela komgodi wanele. Indawo yesembozo sokugcina 2 yindandatho yokuvala yocwaningo kanye nesembozo samafutha esinomgogodla, kanti indawo yesembozo sangaphandle 2 iyibhere eliyinhloko lomgodi, konke okudinga ukugcotshwa ngamafutha kodwa akudingi kuphela ukuhlinzeka ngamafutha kanye ngenyanga, kanti inani lokuhlinzekwa ngamafutha lingu-3 ml.

Ukugcinwa kwezingxenye ezisebenzisekayo

Uma i-concrete twin-shaft mixer isetshenziswa okokuqala noma uma i-concrete ixutshwa ukuze ifinyelele kumamitha-skwele ayi-1000, hlola ukuthi zonke izingalo zokuxuba kanye nezikrwela zikhululekile yini, bese uzihlola kanye ngenyanga. Uma ingalo yokuxuba, i-scraper, i-lining, kanye nezikulufo kutholakala ukuthi zikhululekile, qinisa i-bolt ngokushesha ukuze ugweme ukukhululeka kwengalo ye-stirrer, i-scraper noma ingalo ye-stirrer. Uma i-strifier scraper bolt ikhululekile, lungisa i-scraper bese ubeka igebe phakathi kwamapuleti angezansi akufanele libe ngaphezu kuka-6mm, futhi ama-bolt kufanele aqiniswe.

Umonakalo ezintweni ezisetshenziswayo

1. Susa izingxenye ezonakele. Uma ushintsha ingalo yokuxuba, khumbula indawo yengalo yokuxuba ukuze ugweme ukulimala kwengalo yokuxuba.

2. Uma ushintsha isikrwela, susa ingxenye endala, beka ingalo yokuvuselela phansi bese ufaka isikrwela esisha. Beka ucezu lwensimbi (ubude obungu-100mm ububanzi, ubukhulu obungu-50mm kanye nobukhulu obungu-6mm) phakathi kwesikrwela nepuleti elingezansi ukuze ubophe ibholthi lesikrwela. Uma izingxenye ezindala zisusiwe ngemva kokushintsha ulwelwesi, ulwelwesi olusha lulungisa izikhala eziphezulu nezingezansi kwesobunxele nakwesokudla ukuze ziqinise ngokulinganayo amabholthi.

Ukulungiswa komnyango wokukhipha amanzi

Ukuze kuqinisekiswe ukuvulwa nokuvalwa okuvamile komnyango wokukhipha, indawo yomnyango wokukhipha kulula ukuyicindezela ngesikhathi senqubo yokuvala, okuzoholela ekukhishweni komnyango wokukhipha noma inkinobho yokungenisa yomnyango wokukhipha ingadluliselwa ohlelweni lokulawula. I-mixer ayikwazi ukukhiqizwa. Ngakho-ke, kubalulekile ukuhlanza amadiphozithi azungeze umnyango wokukhipha ngesikhathi.

Isikhathi sokuthunyelwe: Agasti-22-2018