With the development of the market, the demand for prefabricated components is increasing, and the quality of precast concrete components in the market is very different.

Prefabricated component manufacturers are currently concerned about the core of the production process. The quality of concrete in the production of precast concrete directly affects the product performance of the prefabricated component. The decisive factor in determining the quality of the precast concrete is the performance of the mixing host in the precast concrete mixing plant.

At present, what is commonly confused in the industry is whether a planetary concrete mixer or a twin-shaft forced concrete mixer is used in a precast concrete mixing plant. What is the difference between the two concrete mixers in the mixing performance of premixed concrete?

Analysis from stirring device

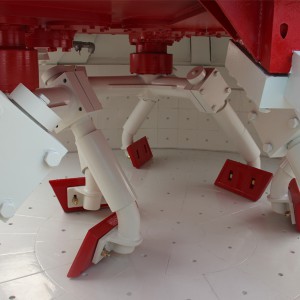

Planetary concrete mixer’s stirring device: The stirring blade adopts a parallelogram design structure. When the stirring is worn to a certain degree, it can be rotated 180 degrees, continue to be used repeatedly, reducing the cost of the customer’s accessories. The stirring arm adopts the clamping block structure design. Increase the use of the blade as much as possible.

The mixing arm is designed in a streamlined manner, which reduces the probability of the material arm, and the design of a wear-resistant jacket to improve the service life of the music mixing arm.

[Planetary concrete mixer's mixing device]

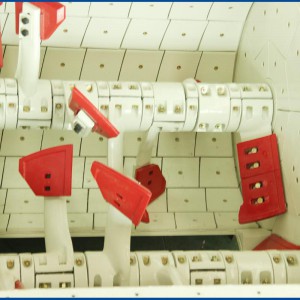

Twin-shaft forced concrete mixer mixing device is divided into blade type and ribbon type two modes, due to structural defects, low blade utilization, mixing arm after a period of time needs to be replaced as a whole, due to the limitations of the layout structure, increase The chances of the material holding the axis and the retracting arm increase the cost of customer maintenance and parts replacement.

The vertical axis planetary concrete mixer can not only meet the requirements of premixed concrete with high stirring efficiency, high mixing quality, and high homogeneity of mixing; because the prefabricated component is directly under the mixing station, there is no secondary stirring in the transport of commercial concrete tankers. Therefore, the homogeneity of a single stirrer is required to be higher, and the homogeneity of only one stirrer is high, so as to reduce the scrap rate of the prefabricated component product and improve the quality of the customer’s finished product. The performance of the superiority of the vertical axis planetary concrete mixer is relative to Two-shaft forced concrete mixers are suitable for the stirring of precast concrete.

Two-shaft forced concrete mixers are suitable for commercial concrete, sludge treatment, waste residue treatment and some industries with low requirements for homogeneity.

Post time: May-16-2018