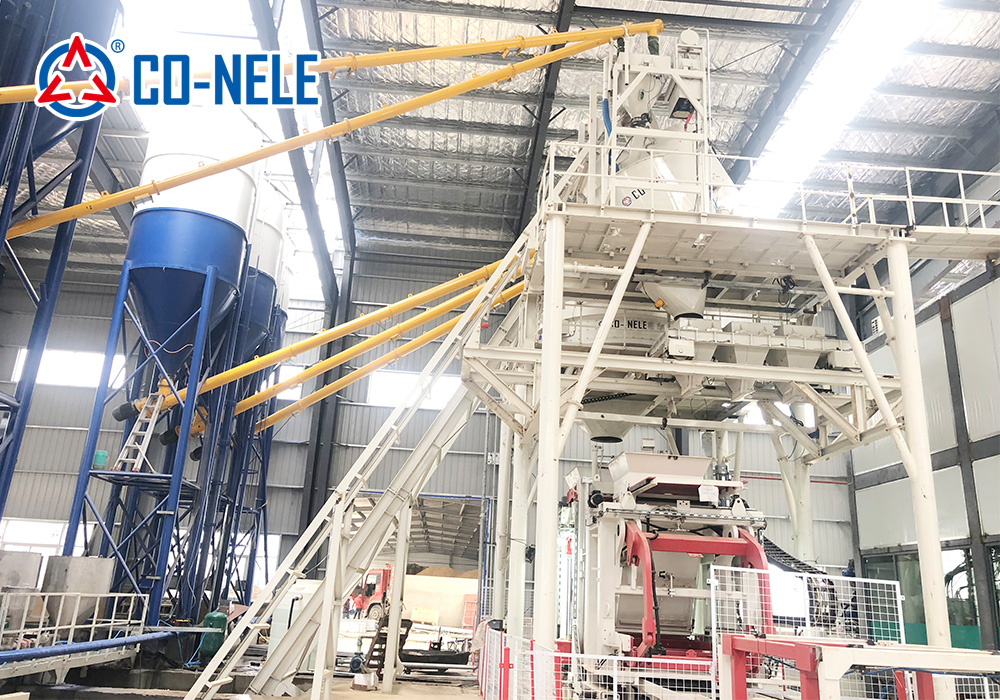

CO-NELE Concrete Mixing Plants and HESS Brick Making Machines: Leaders in Integrated Solutions for Building Materials Production

The perfect fusion of German technology and ingenious craftsmanship provides highly efficient and intelligent equipment solutions for modern building materials production.

In today’s construction industry, efficient and environmentally friendly building materials production equipment has become a mainstream market demand. The combination of CO-NELE concrete mixing plants and HESS concrete brick making machines provides companies with an integrated solution from concrete preparation to finished brick production.

With their German technological heritage, superior performance, and high reliability, these two brands are becoming the preferred equipment for building materials manufacturers worldwide, helping them improve production efficiency and product quality.

1. CO-NELE Concrete Mixing Plants: A Technical Exemplary of Efficient and Uniform Mixing

CO-NELE vertical planetary concrete mixers utilize advanced German technology. Their unique mixing principle and structural design achieve high-speed, uniform mixing of materials with zero dead zones.

This equipment utilizes a combined revolution and rotation motion principle. The mixing blades follow a trajectory that covers the entire mixing drum, ensuring high homogeneity for all types of materials, from standard concrete to high-performance specialty concrete. Core Advantages of CMP Planetary Concrete Mixers:

Uniform Mixing without Dead Spots: The unique planetary mixing motion ensures extremely uniform mixing in a short time, making it particularly suitable for high-performance concrete (such as UHPC) and fiber-reinforced concrete.

Wide Applications: Suitable for a wide range of industries, including building materials, concrete, refractory materials, chemicals, ceramics, and glass.

High Reliability: The hardened gear reducer drive delivers low noise, high torque, strong durability, and long service life.

Intelligent Design: Optional fully automatic lubrication systems, high-pressure cleaning devices, and temperature and humidity testing systems facilitate maintenance and reduce manual intervention.

Conelec also offers the CHS series of high-efficiency twin-shaft concrete mixers. These models feature a patented 60° angled arrangement and an upper-mounted motor belt self-tensioning device, resulting in high transfer efficiency and minimal wear, further expanding customer options.

2. Hayes Fully Automatic Concrete Brick Making Machine: Expert in Precision and Efficiency

The Hayes RH series fully automatic concrete block making machine, inspired by German design and manufacturing standards, holds a significant position in the global high-end brick making equipment market with its exceptional flexibility, precision, and high production capacity. By changing molds, a variety of concrete products can be produced.

Core Product Models:

Hais RH1500: A high-end model equipped with an M-type hydraulic control system, featuring highly integrated hydraulic and electrical systems, and a molding cycle as fast as 10.5 seconds.

Hais RH1400: An economical, high-quality model with a high investment value. Assembled and manufactured domestically in accordance with German standards and component requirements.

Rich Output: One machine can be used for multiple purposes, producing permeable bricks, imitation stone bricks, hollow blocks, curbstones, split bricks, and various specialty concrete components.

3. Powerful Combination: A Perfect Production Chain of Mixing and Molding

The Co-Nel mixer and the Hais brick making machine work together to form an efficient, intelligent production line from raw material processing to finished product output.

The Co-Nel mixer ensures optimal mixing uniformity in every batch, providing the Hais brick making machine with high-quality raw materials, thus ensuring the final bricks have stable mechanical properties, a beautiful appearance, and excellent durability**. This combination is particularly suitable for producing high-value-added concrete products such as PC imitation stone bricks, permeable bricks, and recycled construction waste bricks.

4. Market Competitiveness and Global Recognition

The Co-Nero and HESS brands enjoy a high reputation in the global building materials machinery market:

Co-Nero: ISO9001 and EU CE certified, with over 10,000 users worldwide, is China’s largest mixer production base and a Shandong Province manufacturing champion. It holds 100 patents and exports its products to over 80 countries and regions.

HESS: A brand of the German Topvik Group, with over 150 years of history, its equipment and technology have a wide influence and a high market share in the global concrete products industry. Topvik (Langfang) Building Materials Machinery Co., Ltd. is its key base in China, serving the Asia-Pacific market.

Whether building a new building materials plant or upgrading an existing production line, Co-Nero offers integrated solutions for concrete brick making equipment.

Concrete batching plants are used in concrete brick production to precisely measure and mix concrete ingredients, such as cement, sand, gravel, and water, in precise proportions. This process ensures consistent concrete quality and high strength, which is crucial for producing durable, standardized concrete bricks. Concrete batching plants work in conjunction with brick-making machines to deliver the correct amount of concrete for each brick.

How brick-making batching plants work:

1. Ingredient Storage:

The batching plant stores cement, sand, and aggregates (rock, gravel) in separate bins.

2. Automatic Weighing:

The concrete batching machine automatically meters the required amount of each ingredient according to the user-defined mix ratio.

3. Mixing:

The metered ingredients are then conveyed to the mixer.

4. Delivery to the mixer:

The mixer blends the ingredients to form a uniform concrete mixture.

5. Brick Production:

This high-quality, ready-to-use concrete is then fed into the block-making machine to be formed into bricks. Advantages of Concrete Brick Production:

Quality Control: Ensures all bricks are made with the correct and consistent concrete recipe.

Efficiency: Automated material metering and delivery speeds up the production process.

Durability: High-quality, properly mixed concrete produces strong, durable bricks.

Post time: Aug-26-2025