In concrete paving brick production lines, a revolution in mixing technology is quietly transforming product quality and production efficiency.

In the concrete paving brick production process, the uniformity of the mixing process directly determines the strength, durability, and appearance of the finished bricks. Traditional mixing equipment has long faced problems such as material pilling, uneven color distribution, and dead spots, which CoNele Machinery Co., Ltd.’s innovative planetary mixing technology is gradually addressing.

In the production of colored concrete paving bricks, surface spotting caused by raw material pilling has long plagued many manufacturers.

Uneven material color distribution not only affects the appearance of the paving bricks but also reduces their mechanical properties and service life.

Furthermore, problems such as material sticking inside the mixing drum and difficulty in cleaning significantly reduce production efficiency and increase maintenance costs.

Facing these common industry challenges, Qingdao CoNele Machinery Co., Ltd. offers innovative solutions with its CMP series vertical-shaft planetary mixers.

The Conele CMP series vertical-shaft planetary mixers utilize the countercurrent planetary principle, with a specially designed transmission mechanism achieving opposite rotation and revolution directions.

This motion method creates more intense relative motion between materials, enhancing shear interaction and effectively preventing agglomeration.

Even existing material clumps are broken up and dispersed during this process, ensuring uniform mixing.

For the more demanding mixing of the topping layer, the CMPS750 planetary ultra-fast mixer excels. Its uniquely designed bottom and side scrapers continuously remove residual material from the mixing drum, ensuring no accumulation.

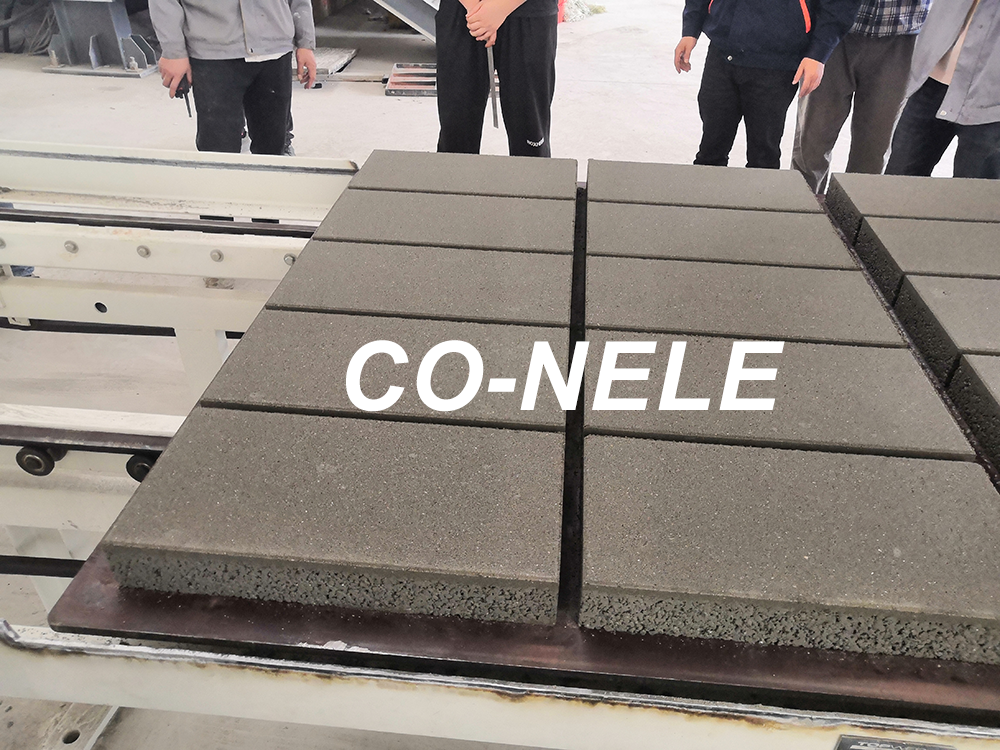

In a typical concrete paving brick mixing plant, a CMP2000 planetary concrete mixer is used for the base material, while a CMPS750 planetary ultra-fast mixer is used for the topping layer.

This configuration fully leverages the strengths of each equipment model, achieving an optimal balance between production efficiency and quality.

The CMP2000, as a base material mixer, can efficiently process dry, semi-dry, and plastic concrete. Its powerful mixing capacity ensures uniform and dense base material.

The CMPS750, designed specifically for fabrics, features a rapid mixing mechanism that effectively prevents pilling, achieves more uniform color distribution, and maintains the surface quality of paving tiles.

04 Technical Advantage: Zero-Dead-Zone Mixing Ensures Quality

The core technological advantage of the vertical planetary mixer lies in its planetary compound motion trajectory.

This design enables the mixing blades to reach every corner of the mixing drum, completely eliminating the dead spots and material accumulation areas common in traditional mixers.

This zero-dead-zone mixing feature is particularly important in the precast concrete industry.

It can meet the requirements of varying concrete quality characteristics, advanced new mix proportions, and non-traditional aggregate mixing.

It can achieve thorough mixing of dry, semi-dry, and plastic concrete, as well as concrete with various mix proportions, in a very short time.

05 Widespread Application and High Industry Recognition

Conele’s vertical planetary mixers not only excel in the concrete paving brick industry but are also widely used in a variety of industries, including precast components, refractory materials, and ceramic building materials.

In July of this year, Xu Yongmo, Honorary President of the China Concrete and Cement Products Association, and his delegation visited Conele Machinery Equipment Co., Ltd. for research and exchange.

Association leaders fully recognized Conele Machinery’s core competitiveness in mixing equipment research and development and the application of scientific and technological achievements.

As a leading company in the mixing equipment industry, Conele Machinery is leveraging its leadership role to inject new momentum into the high-quality development of the industry.

06 Future Prospects: Mixing Technology Continues to Evolve

As the construction industry’s requirements for material performance continue to rise, so too are the demands on mixing technology.

Conele Machinery has achieved a transition from offline to online operations through the MOM digital cloud platform, focusing on four key aspects: lean, automated, networked, and intelligent manufacturing, to create a smart manufacturing workshop.

The introduction of Austrian IGM welding robots and Japanese FANUC fully automatic welding robots for mass production has resulted in overall improvements in product quality, cost reductions, and increased efficiency.

The various mixing equipment with different mixing mechanisms within the laboratory center provide crucial support for advancing industry technological development.

With its unique design and outstanding performance, Coneline Machinery’s vertical planetary mixer is becoming the preferred equipment for a growing number of concrete paving tile manufacturers.

As market demands for paving tile quality continue to rise, this countercurrent planetary mixing technology is expected to become the new industry standard.

From small precast component plants to large brick production lines, from colored floor tile surfaces to various specialty concrete products, Coneline’s innovative mixing solutions are driving the entire industry towards greater efficiency, higher quality, and more environmentally friendly development.

Post time: Oct-13-2025