In the refractory industry, consistent mixing quality is vital to achieving strong, thermally stable fire bricks. The India refractory manufacturer was facing uneven blending of alumina, magnesia, and other raw materials, leading to product inconsistencies and high rejection rates.

Challenge

The customer’s existing mixer failed to deliver homogeneous mixtures, especially when handling high-density and abrasive materials. This affected brick strength, firing stability, and dimensional accuracy.

CO-NELE Solution

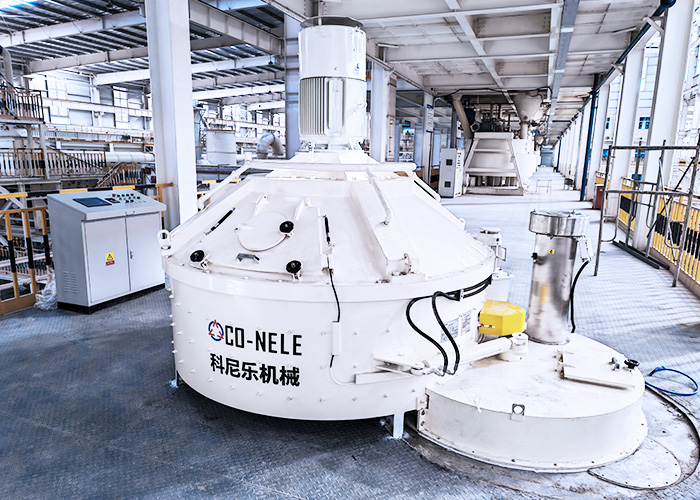

CO-NELE provided two planetary mixers model CMP500, designed for intensive mixing of refractory compounds.

Key features include:

* Planetary motion with overlapping mixing trajectories for complete material circulation

* High-torque transmission suitable for dense refractory batches

* Wear-resistant liners and paddles, extending service life

* Integrated water dosing system for precise moisture control

After installation, the customer achieved:

* 30% higher mixing uniformity, ensuring consistent density and strength

* 25% shorter mixing cycles, boosting production output

* Reduced maintenance and downtime, due to robust wear protection

* Improved workability, enhancing brick forming and compaction

Customer Testimonial

> “The CO-NELE refractory planetary mixer has significantly improved the quality consistency of our refractory batches. It’s a reliable and efficient solution for our high-performance fire brick production.”

CO-NELE planetary mixers provide superior dispersion, reliability, and durability for refractory production lines. With proven success in handling abrasive, high-viscosity materials, CO-NELE continues to support refractory manufacturers worldwide in achieving stable, high-quality fire brick performance.

Post time: Nov-05-2025