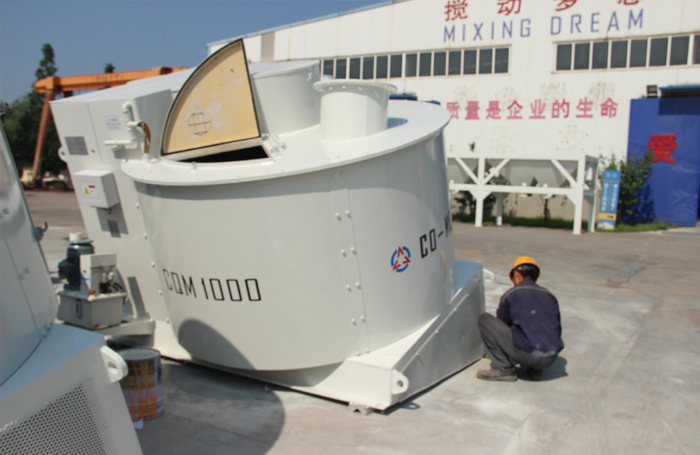

The powerful mixer is recognized in the processing and production of refractory materials. The processing advantages and working principle of the intensive mixer in refractory materials

characteristics and advantages of the intensive mixer

High speed pulverization, countercurrent shearing, strong mixing, dispersion

Excellent uniformity and high mixing efficiency

Significant mixing effect of viscous material and powder

Low wear, small structural repairs, no dead ends

the principle of mixing the intensive mixer

Material mixing status

The rotary mixing drum continuously sends the material to the high speed blade to form a counterflow flow with a large speed difference, and the turbulent state is formed by the impact of the blade.

The multi-functional unloading scraping wall system can effectively prevent the mixture from adhering to the wall of the mixing drum, and ensure that the material forms a strong vertical component, enhances the stirring effect, and accelerates the unloading after the stirring is completed, shortening the unloading time.

?Fourth, the unique structure

Vertical rotor with high wear-resistant blades, blade shape and quantity are determined by materials, special positioning discs and tools for easy blade replacement

Rotary cylinder

Outer protective housing, special sealing device for housing and rotating cylinder

Inner wall lining can be designed for material properties

Unique and practical unloading mechanism

Stable and reliable PLC control system

Post time: Jul-17-2018