Amid the transformation and upgrading of the refractory industry, the 500-liter planetary vertical shaft mixer, with its superior mixing performance and energy-saving and environmentally friendly features, is becoming a hidden engine driving high-quality development in the industry.

In refractory production, mixing, as a key process step, directly determines product quality and performance. The global refractory mixer market is experiencing significant growth and is expected to reach significant scale by 2030.

Against this backdrop, the 500-liter planetary vertical shaft mixer, with its unique design and superior performance, is rapidly gaining popularity among refractory manufacturers, becoming a key driver of the industry\’s transformation and upgrading.

01 Industry Status and Challenges

The refractory mixer industry can be divided into two categories based on product type: wet mixing and dry powder mixing.

Traditional refractory mixers have long faced numerous pain points, including industry issues such as uneven mixing and dead spots, as well as material sticking and leakage.

Furthermore, overcapacity and competition from low-end products are also challenges facing the industry. These issues have severely hampered the improvement of refractory product quality.

02 Technological Breakthroughs in Planetary Mixers

A planetary vertical shaft mixer uses a bladed planetary shaft installed within a drum, which exerts a strong, forced mixing force, such as squeezing and tumbling, on the refractory material during rotation.

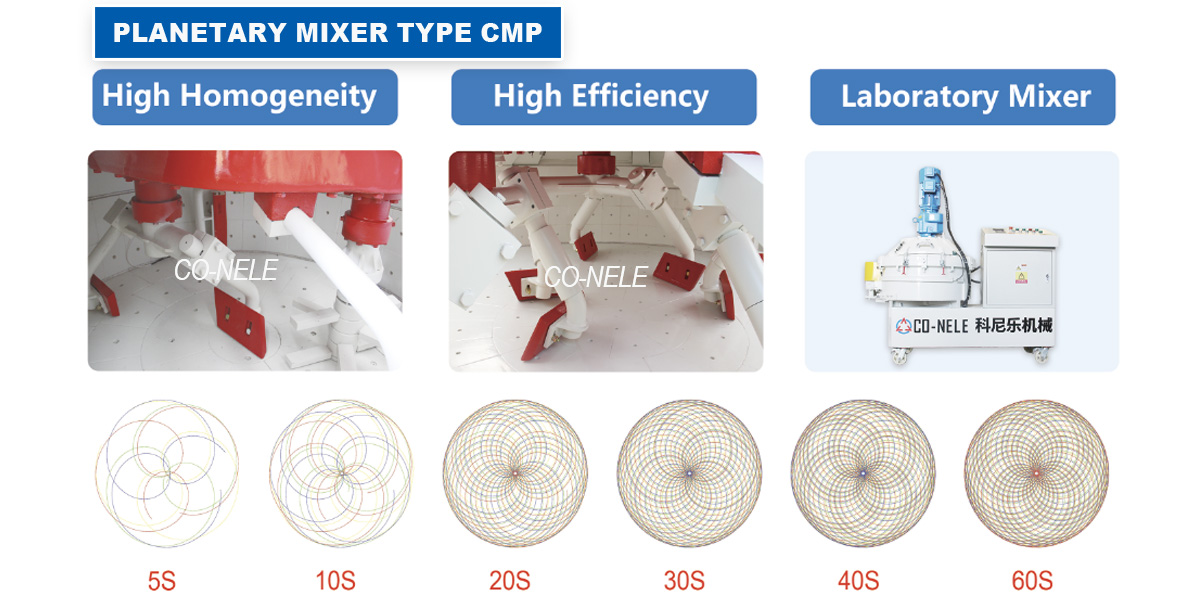

This design achieves highly uniform mixing of materials, achieving complete material coverage in just 5 seconds.

It utilizes a planetary operating mode, organically combining orbital and rotational motion. This motion trajectory is an acceleration mode, providing rapid and energy-saving mixing. The trajectory curve features a progressive, increasingly dense structure.

The 500-liter planetary mixer has a discharge capacity of 500L, a feed capacity of 750L, a theoretical throughput of ≤25m³/h, and a rated mixing power of 18.5kW.

03 Significant Advantages and Application Value

Compared to traditional refractory mixers, the planetary vertical shaft mixer has a more complex operating trajectory. Its specially designed vertical structure ensures ample mixing space within the material.

Planetary mixers are energy-efficient and environmentally friendly, operate silently, and their single-motor drive effectively reduces equipment operating costs. The equipment self-regulates during mixing, significantly reducing energy consumption.

This equipment has a wide range of applications, suitable not only for various high-quality refractory materials and glass ceramsite, but also for mixing in brick-making production lines and other applications.

04 Market Response and Industry Impact

The planetary vertical shaft mixer developed by Qingdao Co-nele boasts excellent homogeneity, high efficiency, energy saving, and environmental friendliness, earning it a favorable response in the refractory castables market.

The advent of the planetary mixer has enabled high-quality, low-energy consumption refractory mixers, laying a solid foundation for future production and preparation in the refractory castables industry.

With the innovation and upgrade of the planetary mixer\’s mixing process, it has further driven the refinement of mixing and preparation in the refractory castables industry.

05 Future Development Trends

Against the backdrop of \”carbon neutrality,\” the refractory mixer industry is moving towards reducing carbon emissions and increasing carbon absorption. Clean alternative technologies and electric energy replacement technologies are becoming key technical directions.

Planetary mixers, with their unwavering dedication and continuous upgrades, have once again reignited the industry\’s mixing industry with their smooth and reliable mixing capabilities.

In the future, with ongoing technological advancements and changing market demands, planetary mixers will continue to evolve, providing even more efficient and environmentally friendly mixing solutions for the refractory industry.

Today, an increasing number of refractory manufacturers are adopting this advanced equipment to improve product quality and market competitiveness, seizing opportunities in the industry\’s transformation and upgrading.

Post time: Sep-11-2025