Lithium battery hybrid technology

Economical and efficient - High environmental performance - Saves time - Easy to maintain

The preparation technology in the field of lead-acid lithium batteries is outstanding!

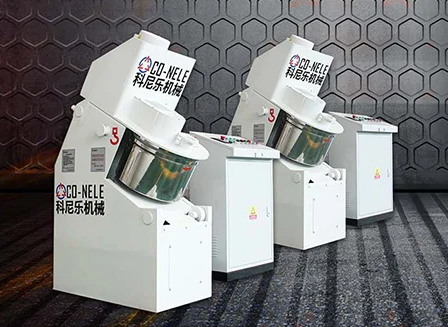

CO-NELE intensive mixer can meet the special mixing requirements of lithium battery slurry.

Adapting to various mixing and blending processes, it can be efficiently used for preparing battery pastes, battery materials, and battery slurries.

Strong mixing performance, comprehensive supporting services, and providing customized solutions for individuals

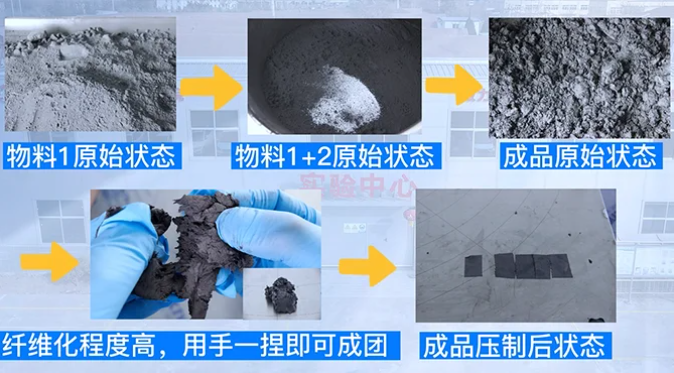

CO-NELE Pioneer in Dry Electrode Preparation Technology

The unique mixing tool can thoroughly break up the agglomerates in the raw materials, achieving the best dry mixing, encapsulation and fiberization effects in a short period of time. It is suitable for extremely fine-grained materials.

Fibering treatment involves covering the active materials with a polymer binder without disrupting the structure of the material particles.

Pioneer in battery materials and electrode preparation!

Preparation of cathode materials and electrolytes for all-solid-state batteries, as well as the preparation of separators

Lithium battery anode body mixing and cathode material coating, lithium battery anode material mixer

Integrated equipment for dry mixing and homogenization of lithium battery slurry, high solid content slurry preparation, dry electrode preparation

Provide users in the battery industry with customized solutions that serve multiple purposes in one device.

Battery slurry preparation, integrated equipment for dry mixing and pulping, 30 minutes per batch, automatic continuous process monitoring, ensuring the best quality and consistency of the slurry.

The unique CO-NELE Hybrid System advantages

Leke can integrate the complex process (lasting 4 hours) into a single processing equipment for operation. (Within 20 minutes)

CO-NELE Lithium Battery Mixers Production Technology: Rotating mixing disc and eccentric mixing tools! During the mixing process, the mixing disc pushes the materials towards the rotating rotor, without creating any dead zones. The fixed multi-functional scraper guides the materials near the mixing disc back into the material flow.

CO-NELE not only focuses on the preparation and production of raw materials, but also provides advanced and efficient production processes for the production of positive electrodes, negative electrodes and separator layers.

Battery slurry preparation, integrated equipment for dry mixing and pulping, 30 minutes per batch, automatic continuous process monitoring, ensuring the best quality and consistency of the slurry.

Explosion-proof design is applied in the pulping system:

Dry mixing and dispersion of the positive and negative electrode pastes; granulation of particles with a diameter of 1mm, or granulation of other particle sizes in liquids containing water or other solvents; dissolution and granulation of electrolytes or high molecular polymers; production of aqueous solutions or solventable plastic slurries; in the positive suspension and negative slurry of Konele vacuum technology, there will be absolutely no bubbles.

Large-scale Intensive mixer for lithium batteries

Multifunctional rotor scraper and side scraper

Lithium battery positive and negative electrode material mixer

Model of Lithium battery hybrid Mixers

Intensive Mixer (100-12000liters)

Dry Electrode Mixer